- Products

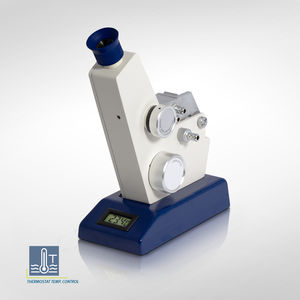

- Digital refractometer

- A. KRÜSS Optronic GmbH

Digital refractometer PR21Sprocessin-linewith touchscreen

Add to favorites

Compare this product

Characteristics

- Type

- digital

- Applications

- process

- Configuration

- in-line

- Other characteristics

- with touchscreen, with USB port

Description

Accurate results for automatic and continuous process control

The inline process refractometers PR21S and PR21S-T are installed in pipelines of production facilities in order to control and regulate the concentration, mixing and fermentation processes. Thanks to the standardised connections, the measurement devices can be easily installed in pipelines. The measuring chamber is made of stainless steel, the measurement prism consists of scratch-resistant and especially chemical-resistant sapphire and is designed to prevent solids from sticking.

• Determination of the refractive index directly in the line within a range of nD 1.3200–1.5200* and 0–95 %Brix

• Measurement intervals from 3 to 60 seconds selectabler

• Automatic temperature compensation (%Brix and freely definable for customer-specific products)

• Integrated sensor for temperature monitoring

• User-defined scales

• Stainless steel measurement chamber that meets all the requirements of the food and pharmaceutical industry, CIP/SIP capable

• Sample prisms, made of scratch-proof and chemical-resistant sapphire

• Cleaning via process cleaning processes

• PR21S-T model can be coupled with water cooling and is suitable for process temperatures up to 120 °C

•Easy connection with process control system or MPC via analogue outputs (0/4-20 mA)

• Display for the visual monitoring is also available

• Conformity with global standards and norms

*The measurement range of your device will be configured individually based on the specifications made in the PDF requirement profile provided by us. A binding order only comes into effect once you have returned the fully completed form to us.

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.