- Laboratory

- Sample management

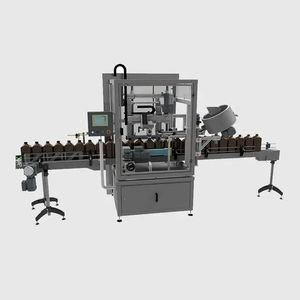

- Bottle capping system

- Albertina Machinery

Bottle capping system CAPLINE CNfor the pharmaceutical industryautomaticrotary

Add to favorites

Compare this product

Characteristics

- Product applications

- bottle

- Use domain

- for the pharmaceutical industry

- Operation

- automatic, rotary

Description

This is the basic version of automatic single-headed capping machines. The bottles and canisters are stopped under the capping head with the help of sidebands. The caps are aligned using a band feeder or a rotation aligner and transported on a conveyor to a pick-and-place station, which passes the cap under the capping head. The capping head is set on the cap and tightens it to the required screw torque. The capacity of the machine is 1,500 bottles per hour.

Machine frame mounted on height adjustable feets

Stainless Steel conveyor with adjustable guide rails and with delrin or stainless steel top slat band.

Input and output gates for stopping the packaging under the closing head

Rotary caps orientator on top of the machine

Caps chute with sensor to detect cap presence

Pick and Place device

Capping head with adjustable torque

Sensor for detecting packaging in the sealing compartment

Sensor to detect full outfeed conveyor

Control panel with touch screen

CE safety guards

Format parts for one type of bottle and one type of a cap

Cap inventor with tray

Side belt system for stopping bottles below the

capping head

ATEX configuration

Chemical proof configuration

Remote connection

VIDEO

Catalogs

No catalogs are available for this product.

See all of Albertina Machinery‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.