- Laboratory

- Laboratory medicine

- CAD software

- Amann Girrbach

- Products

- Catalogs

- News & Trends

- Exhibitions

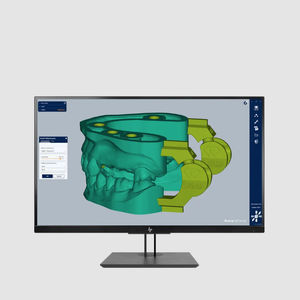

CAD software Ceramill Mindfor dental prosthesis designCAMlaboratory

Add to favorites

Compare this product

Characteristics

- Function

- CAD, for dental prosthesis design, CAM

- Applications

- laboratory, dental

Description

The Ceramill Mind CAD software impresses with its intuitive UI for the fabrication of a wide range of indications and is seamlessly integrated into the Amann Girrbach workflow.

Features

Simple operability, process reliability and precision are the outstanding features when working with Ceramill Mind. The user guidance of the CAD program is based on the standard laboratory workflow and significantly simplifies the process of digital denture fabrication. The Ceramill Mind forms the basis for the design of numerous indications. In addition, special patient restorations can be implemented via upgrade modules - such as the Ceramill M-Gin for implant bridges with a gingiva component or Ceramill-Splint for the fabrication of splints.

INTEGRATED IN THE AG-WORKFLOW - EFFICIENT, REPRODUCIBLE AND SAFE

The design software is integrated into the Amann Girrbach workflow. This means that all components, both the hardware, such as the milling machine and materials, as well as the software, such as milling strategies and nesting software, are matched to each other and validated. This allows for a consistent, seamless design for precisely fitting results..

USER GUIDANCE - INTUITIVE AND ACCORDING TO DENTAL TECHNOLOGY LOGIC

A workflow based on dental technology logic enables considerable time savings in the daily work routine.

FUTURE-PROOF WORKING

Continuous enhancements of CAD software upgrade modules for the design software guarantee future-proofing in the laboratory and in practice.

HIGH FLEXIBILITY

Ceramill Mind sends and reads STL data, creating the highest possible flexibility in workflows.

VIDEO

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.