- Medical Technical Facilities

- Hospital infrastructure

- Medical oxygen generator

- AMCAREMED TECHNOLOGY

Medical oxygen generator mobileplug-and-playon site

Add to favorites

Compare this product

Characteristics

- Applications

- medical

- Configuration

- mobile, plug-and-play, on site, container

- Type

- PSA

- Other characteristics

- high-purity

- Flow rate

Min.: 5 m³/h

(176.573 ft³/h)Max.: 200 m³/h

(7,062.933 ft³/h)- Oxygen concentration

Min.: 90 %

Max.: 96 %

93 %

- Oxygen pressure

Min.: 0.55 MPa

Max.: 3 MPa

- Oxygen purity

Min.: 90 %

Max.: 96 %

Description

The container oxygen generator is a complete set of oxygen generators pre-completed in a container. It is a mobile plug-and-play device, with the advantages of low cost, small area, simple operation, easy maintenance, quick on-site oxygen production, convenient switching, and no pollution.

Product Detail

AmcareMed containerized oxygen generator system can be regarded as a mobile oxygen center, which can continuously supply oxygen for different work sites. It can be widely used in medical, petrochemical, ozone production, and other industries and fields.

The system uses air as raw material and zeolite molecular sieve as adsorbent to separate oxygen from air by pressure swing adsorption technology

Working Principle

The oxygen generator system mainly consists of air compressor, dryer, PSA oxygen generator, and booster compressor.

The air is compressed to working pressure by screw air compressor and then enters the dryer through the filter to remove oil, water, and dust. Finally, enter the air tank to store the necessary air for the PSA generator. Clean compressed air enters the PSA generator to separate oxygen and nitrogen.

Adsorption tower filled with zeolite molecular sieves. Molecular sieves adsorb nitrogen and allow oxygen to stream through. Adsorbent releases the impurities (mainly nitrogen) to complete adsorbent regeneration, oxygen accumulates on the top of the absorption tower, then enters to the oxygen tank.

After filtering, oxygen can be directly connected to the hospital oxygen pipeline or enter to booster compressor. After pressurization, oxygen is filled into the cylinder through the cylinder filling ramp.

VIDEO

Catalogs

No catalogs are available for this product.

See all of AMCAREMED TECHNOLOGY‘s catalogsRelated Searches

- Oil-free air compressor

- AMCAREMED medical compressor

- Positive-displacement vacuum pump

- AMCAREMED gas outlet

- Hospital vacuum pump

- 1-workstation air compressor

- Piston air compressor

- Air compressor with air dryer

- Silent air compressor

- Medical oxygen generator

- Digital control unit

- Rotary vane vacuum pump

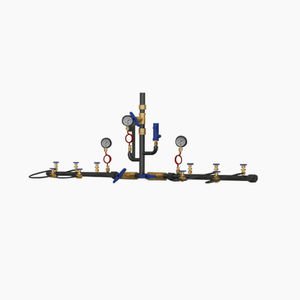

- AMCAREMED manifold

- Medical device controller

- Vacuum system

- AMCAREMED medical gas manifold

- Medical controller

- O2 gas mixer

- Lubricated vacuum pump

- PSA oxygen generator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.