- Laboratory

- Physico-chemical analysis

- EDXRF spectrometer

- Angstrom Advanced Inc.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

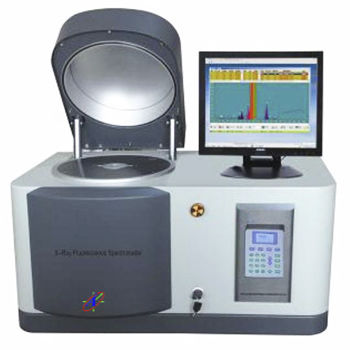

EDXRF spectrometer ADX-9800transferbenchtop

Add to favorites

Compare this product

Characteristics

- Type

- EDXRF

- Applications

- transfer

- Configuration

- benchtop

Description

The ADX9800 is a powerful EDXRF that has built in multiple collimators and for the various testing parameters. The vacuum chamber allows for highly precise results and the ability to test elements from Sodium (Na) to Uranium (U).

Hardware

Si-Pin/SDD Detector Ultra High Resolution Detector

Electro-refrigeration semiconductor detector with energy resolution: 130eV

Energy response range: 1-50 keV

Be window thickness: 50 μm

It is used to detect the characteristic X-rays of the samples, and then collect the information and amplify it.

X-ray Tube

Service life is more than 20,000 hours

Emitting X-rays towards the samples

Target: Mo/Ag (please ask Angstrom for your application)

High/Low Voltage Power Supply

Tube Voltage: 5~50kV

Tube Current: 5μA - 1000μA

Supplying exclusive power to X-rays tube

Voltage regulation/adjustment rate: 0.01% (from zero load to full load)

Voltage stability of 8 hrs: 0.05%

Multi-Channel Analyzer

It is used to conduct data processing of the collected information, and transfer the results to the computer.

High Resolution Camera

In-Built High Resolution Camera for Sample Observation and Placement.

Vacuum system

Provide vacuum condition for the samples during the test. Vacuum degree reaches 10-2 Pa in 10 second. High vacuum area reaches 10-1 – 10-5 Pa.

Software

Functions: RoHS Analysis, Full Element Analysis and Plating Thickness Analysis.

It can conduct a video observation on the placement of the samples.

It can analyze dozens of elements simultaneously and it will only take 1 to 3 minutes.

It can conduct qualitative analysis automatically and report accurately.

Catalogs

Other Angstrom Advanced Inc. products

XRD, XRF, X-ray Flaw Detector

Related Searches

- Microscopy

- Compound microscope

- Laboratory microscope

- Tabletop microscope

- Spectroscope

- Digital microscope

- Benchtop spectroscope

- Research microscope

- 3D microscope

- Environmental analysis spectrometer

- Multipurpose microscope

- AFM microscope

- X-ray spectrometer

- Scanning probe microscope

- Hand-held spectrometer

- Spectrometer with touchscreen

- Transfer spectrometer

- EDXRF spectrometer

- Ellipsometer

- Spectroscopic ellipsometer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.