Medical gas manifold automatic

Add to favorites

Compare this product

Characteristics

- Applications

- for medical gas

- Options

- automatic

Description

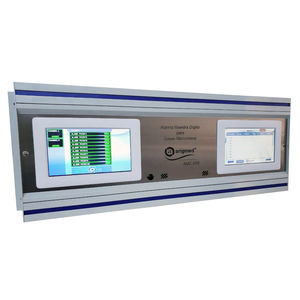

Control System:

• High speed electronic PCB with 7 " full color LCD display, touch screen control.

• 110-220 vac normally open electric valve.

• Non-return valves

• 4-20Map high and low pressure transducers

Graphics:

• High and Low pressure Display readings for primary and secondary deward cylinder headers in real time.

• High and Low pressure Display readings for manifold final pressure delivery in real time.

• Pressure units.

• Alarm signais.

Signals (Alarms):

• Low delivery pressure alarm.

• Main cylinder header empty alarm.

• Backup cylinder header in use alarm.

• High pressure alarm (above of 20% of nominal pressure).

• Leak alarm (25% pressure drop detected in the reserve or stand by cylinder header).

Minimum Pressure of Deward Cylinders:

• 230 PSI

By-pass System:

• 2 low pressure final line regulators with manual isolation stainless steel bail valves (one regulator in use and the other in reserve).

Over-pressure and vent valve system:

• Interconnected circuit protection system of relief valves, over-pressure guided to the exterior of cabinet manifold.

Comunication System:

• 5 alarms Relay type (Dry Contact) connections to a remote master panel alarm connection, as well an intégration of a remote monitoring and administration system BMS (Building

Management System) common language based on relay switching.

• Two-wire Modbus RTU RS485 communication in slave mode for monitoring pressures in PSI units and alarm conditions from a BMS (Building Management System), SCADA (Supervisory

Control and Data Acquisition) system orany equipment configured as master panel.

• Main Cilynder Header use choosing button.

Catalogs

No catalogs are available for this product.

See all of Arigmed‘s catalogsRelated Searches

- Oil-free air compressor

- Medical air compressor

- Dry vacuum pump

- Positive-displacement vacuum pump

- Medical gas outlet

- Hospital vacuum pump

- Laboratory gas generator

- Silent air compressor

- Pressure swing adsorption gas generator

- Rotary vane vacuum pump

- Manifold

- Medical gas manifold

- Lubricated vacuum pump

- Anesthetic gas alert system

- Plug-in type vacuum regulator

- Scroll air compressor

- Lubricated air compressor

- O2 gas generator

- Modular air compressor

- Medical gas medical alert system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.