BS type outlet AGA MC70oxygen

Add to favorites

Compare this product

Characteristics

- Type

- BS type

- Options

- oxygen

Description

Primary Valve (Back Assembly):

• Brass made Primary valve 360°rotation, copper piping extention "K" type 10mm (internai diameter).

• Polypropylene injection ckeck valve.

• Thermoplastic injection TPVs FDA grade seals.

• Wall and Architectural (Patient Bedhead Units) Hardware Mounting Modular assembly, carbon steel sheet 18 gauge nickel finish made.

• Ceiling Hardware Mounting Modular assembly available, upon request.

• Stainless steel spiral locks.

• "Pin-Guide" No cross connection safety system die-cut corresponding to a spécifie medical gas type to Rough-in assembly insertion.

Secondary Valve (Rough-in Assembly):

• Stainless steel front plate made with brass feeding valve, it includes a plunger for connection and disconnection of secondary equipment. fastening to the primary valve is by millimeter

screws.

• Inlet stairs connection for each spécifie gas correspond to AGA MC-70 (SWEDISH) technology.

• Brass made check valve.

• Thermoplastic injection TPVs FDA grade seals.

• Stainless steel spiral locks.

• ABS plastic injection trim wall plate chrome finish, same material to architectural equipments trim plate, chrome finish.

• "Pin-Guide" No cross connection safety system corresponding to a spécifie médical gas type to Back-assembly réception.

• zamak chrome finish trim wall plate option (upon request).

Medical Gas Outlet Flow:

• 240 L.P.M. gas flow (if diameters of the main médical gas piping allow it).

• 90 L.P.M. to médical vacuum extraction (if diameters of the main médical vacuum piping allow it).

Load Capacity:

450g Maximum load capacity.

Catalogs

No catalogs are available for this product.

See all of Arigmed‘s catalogsRelated Searches

- Oil-free air compressor

- Medical air compressor

- Dry vacuum pump

- Positive-displacement vacuum pump

- Medical gas outlet

- Hospital vacuum pump

- Laboratory gas generator

- Silent air compressor

- Pressure swing adsorption gas generator

- Rotary vane vacuum pump

- Manifold

- Medical gas manifold

- Lubricated vacuum pump

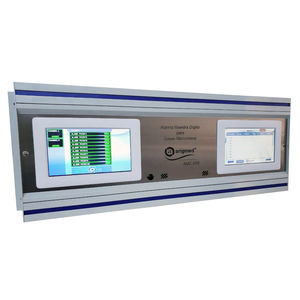

- Anesthetic gas alert system

- Plug-in type vacuum regulator

- Scroll air compressor

- Lubricated air compressor

- O2 gas generator

- Modular air compressor

- Medical gas medical alert system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.