- Laboratory

- Sample management

- Laboratory reagent dispenser

- Arista Biologicals

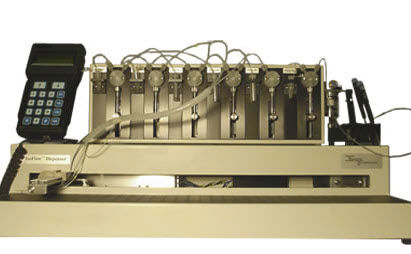

Laboratory reagent dispenser Imagene IsoFlow™benchtop

Add to favorites

Compare this product

Characteristics

- Applications

- laboratory

- Configuration

- benchtop

Description

The IsoFlow™ Dispenser is an integrated system which precisely dispenses liquid reagents in lines onto membranes for the production of immunochromatographic diagnostic test strips. IsoFlow™ accurately and repeatedly applies a continuous reagent line onto the solid medium.

Digital Control

IsoFlow™ uses digitally controlled positive displacement pumps in combination with precision nozzles to develop a uniform stream of reagent. The nozzles are moved over the membrane using a digitally controlled carriage resulting in a fine line of reagent on the membrane with an inherently uniform reagent density (uL/mm).

Optimization

IsoFlow™ simplifies the development, optimization, and manufacture of diagnostic test strips by allowing the operator to easily vary the dispense rate by entering the desired value (in uL/mm) into IsoFlow’s™ hand-held terminal. There is no need to “recalibrate” between settings.

The Low Contact Pressure

The IsoFlow™ Low Contact Pressure (LCP) nozzles allow for greater flexibility in operating parameters than non-contact type dispensers. Reagent delivery rates below 0.01 uL/mm are possible with carriage speeds from 10-300 mm/s. The nozzles typically have larger inside diameters (ID) than non-contact type nozzles. The larger ID lowers shear stress on the fluid, allows lower dispense pressures, and greatly reduces the chance of clogging.

The key to the LCP technology is the flexible nozzles. Variations in the membrane thickness cause the nozzles to flex a little more or less so that the contact with the membrane is always maintained. The contact pressure is so low that there is no significant mechanical stress on the membrane.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Arista Biologicals ‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.