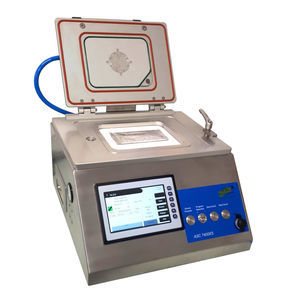

Integrity tester ASC 7400FCCITfor the pharmaceutical industryfor clean rooms

Add to favorites

Compare this product

Characteristics

- Tested parameter

- integrity, CCIT

- Applications

- for the pharmaceutical industry, for clean rooms, for packaging

- Operating mode

- automatic, semi-automatic, manual

- Configuration

- benchtop

Description

The ASC 7400F range was developed specifically for rigid packaging, such as vials, syringes, cartridges, bottles, etc.

Contrary to dye tests, the instrument allows accurate quantification of the level of integrity, without affecting the container or its content.

Vacuum decay / pressure decay method

The product to be tested is placed in a test chamber, in which subsequently a vacuum or positive pressure is created, depending on the application.

After isolating the test chamber, the variation of the pressure is measured over a certain time. This variation is an accurate reflection of the level of integrity of the container.

This deterministic integrity test method is recommended by the FDA as a replacement for traditional dye testing.

A specific function was developed, which checks the complete measurement chain and certifies each measurement result instantaneously.

Ergonomics have also particularly been considered, no force is needed from the operator, the instrument provides the clamp load to ensure the test chamber is hermetically sealed.

Loading and unloading is quick and easy.

Different types and sizes containers may be tested with the same instrument thanks to interchangeable test chambers, offering great flexibility.

A special version, ASC 7400F5, allows simultaneous testing of 5 vials/syringes in order to facilitate the inspection of larger quantities.

The instruments may also be integrated in production lines, with automatic loading/unloading, if a continuous inspection is required.

We have designed our instruments so they can be adapted to products with very different characteristics.

VIDEO

Catalogs

ASC 7400 F5

2 Pages

ASC 7400 F

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.