- Medical & Pharmaceutical industry

- Medical industry

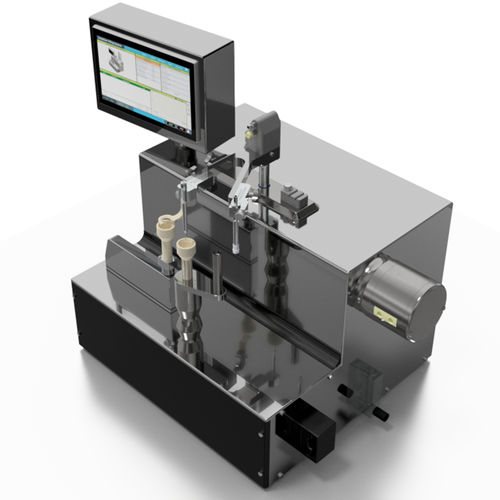

- Closing machine for the pharmaceutical industry

- AST Automated Systems of Tacoma

Closing machine for the pharmaceutical industry CFScompactfor vialssyringe

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Applications

- for the pharmaceutical industry

- Configuration

- compact

- Container type

- for vials, syringe

- Other characteristics

- semi-automatic, automatic

Description

AST’s Container Filling System (CFS) is a bench-top, semi-automatic machine used for the filling of pre-filled syringes and cartridges, and the filling and stoppering of vials and bottles. The system is designed to meet the demanding requirements for small batch processing of sterile injectable products.

The Container Filling System was designed with cGMP in mind. Its compact, aseptic design provides complete compatibility with cleanrooms, bio-safety cabinets, laminar airflow hoods, and aseptic isolator environments.

The system’s versatility, features, and compact size make it ideally suited for labs and cGMP small batch filling applications.

Consistent & Accurate Container Filling

The Container Filling System is integrated with an advanced product dispense system that provides consistent and accurate product dispensing. The integrated peristaltic pump provides accurate dispensing with minimal product shear while using a pre-sterilized single-use fluid path. When integrated with an electronic weigh scale, the system can fill the container while measuring the dispensed material and providing automatic fill adjustments to the pump as required. The system’s electronically controlled axis inserts the filling needle into the container and slowly lifts to minimize shear, foaming or product agitation.

Consistent & Accurate Container Filling

The Container Filling System is integrated with advanced system features to provide consistent and accurate product dispensing. The system is integrated with a peristaltic pump that provides accurate dispensing with minimal product shear.

VIDEO

Catalogs

GENiSYS® Lab

2 Pages

Other AST Automated Systems of Tacoma products

GENiSYS® Lab

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.