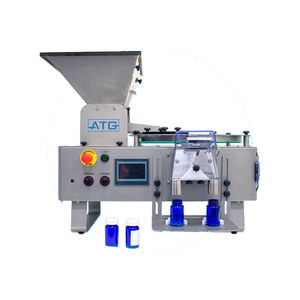

Automated filling machine RoboCAPvolumetricbenchtopfor capsules

Add to favorites

Compare this product

Characteristics

- Operational mode

- automated

- Type

- volumetric

- Configuration

- benchtop

- Product applications

- for capsules

- Container type

- bottle, for cartridges

- Application domain

- for the pharmaceutical industry

- Options

- with capping system

- Production capacity

Min.: 500 p/h

Max.: 8,000 p/h

- Weight

23 kg, 30 kg, 45 kg

(50.7 lb, 66.1 lb, 99.2 lb)- Width

381 mm, 485 mm, 699 mm

(15 in, 19.09 in, 27.52 in)- Height

472 mm, 585 mm, 590 mm

(18.58 in, 23.03 in, 23.23 in)- Depth

500 mm, 584 mm, 610 mm

(20 in, 23 in, 24 in)

Description

Our RoboCAP Volumetric (VF) systems are engineered to maximize efficiency in low-volume product filling (up to 5ml), achieving a precise +/- 2.5% filling accuracy through advanced backpressure, heating, and volumetric displacement

technologies.

With the same speed and consistency as our other RoboCAP systems, clients can scale production by upgrading to two nozzles with heating and mixing or four nozzles without heating—tailored to meet every company’s unique production needs.

Dual Actuated VF+ Dispensing Nozzle

The VF+ Dispensing Nozzle sets a new standard for precision and control. Designed to handle even the thickest oils—such as live resin, rosin, liquid diamonds, and RSO—with ease, it requires significantly less heat, preserving the quality of your product.

Experience a 50% faster draw and dispense rate per shot, all while maintaining an outstanding precision rating of 2.5%. Capable of filling up to 2ml of product with minimal waste, the VF+ ensures you get exactly the amount you need—every time.

Pressure Vessel

Our bottom-out pressure vessels are engineered with back pressure to ensure smooth, even product flow through the tubing, minimizing waste and reducing the risk of air bubbles. Available in stainless steel and ranging in sizes from 1 liter to 10 gallons, each vessel is fully compatible with our mixers and heating systems, providing uniform heat distribution and a cleaner, more efficient filling process.

For high-viscosity, time-sensitive products like gummies, an accurate and efficient filling system is essential to optimize production.

VIDEO

Catalogs

No catalogs are available for this product.

See all of ATG Pharma Inc.‘s catalogsRelated Searches

- Filler for the pharmaceutical industry

- Automatic filler

- Bottle filler

- Table filler

- Capsule filler

- Semi-automatic filler

- Volumetric filler

- Filler with capping system

- Counting machine for the pharmaceutical industry

- Capper for the pharmaceutical industry

- Benchtop filling machine

- Syringe filler

- Automatic counting machine

- Bottle capping system

- Tabletop capper

- Capsule counting machine

- Cartridge filling machine

- Semi-automatic capping system

- Bottle counting machine

- Benchtop counting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.