- Laboratory

- Sample management

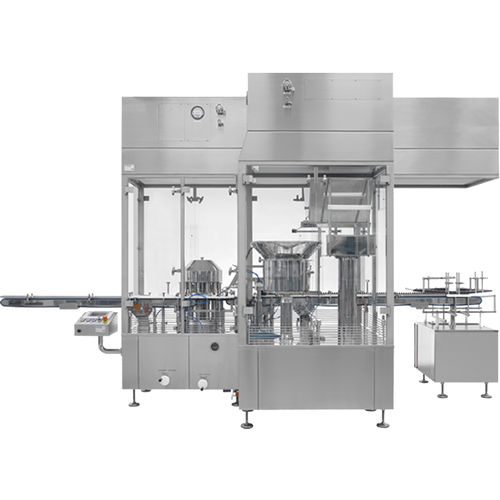

- Vial capping system

- AWS BIO PHARMA TECHNOLOGIES

- Products

- Catalogs

- News & Trends

- Exhibitions

Vial capping system for the pharmaceutical industryrotaryin-line

Add to favorites

Compare this product

Characteristics

- Product applications

- for vials

- Use domain

- for the pharmaceutical industry

- Operation

- rotary, in-line, pressure

- Other characteristics

- floor-standing

Description

OUR ASEPTIC CAPPING SYSTEMS

Our Aseptic Capping Systems process vials, cartridges, syringes and ampoules

Moreover, in-line transport and small width reduces the volume to be monitored and sterilized

Reduced particle generation

Continuous monitoring of the viable and non-viable particles

Vibration Generator for the bowl of aluminum caps

Seal flip-off or tear-off caps (optional)

Install different closing stations (optional)

Further, optional monitoring of the applied pressure during the sealing process is available

In-line control for cap presence detection

Optional standard protection hood

Lastly, all Systems are in compliance with cGMP, GAMP and 21CFR Part11 requirements

VIDEO

Other AWS BIO PHARMA TECHNOLOGIES products

Aseptic Fill-Finish Systems

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.