- Medical & Pharmaceutical industry

- Medical industry

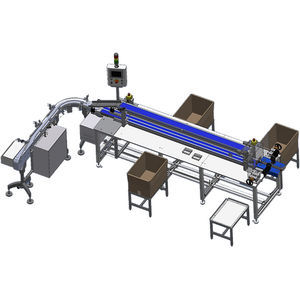

- Automatic inspection system

- b+b Automations- und Steuerungstechnik GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Automatic inspection system LISfor the pharmaceutical industryin-line

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Operational mode

- automatic

- Applications

- for the pharmaceutical industry

- Other characteristics

- in-line

Description

Billions of variable data labels are used every day. Variable data labels enable product tracking and tracing, streamline workflows, ensure brand protection and provide critical consumer information. Thus, labels offer a high level of functionality.

It is important that the label is legible and correctly applied, regardless of the purpose for which the label is used. Label inspection systems can ensure these requirements.

The system detects missing pressure points, verifies variable data such as serial numbers, dust inclusions, etc.

Label inspection system for different applications:

Label inspection systems are used to check print quality, control the production process and verify labels with variable data

Bar codes and unique identifiers can also be read at high speeds

Detailed print quality verification to identify print quality errors associated with ingredients, dosing and application information

Challenging, highly reflective surfaces such as holograms and foils as well as ultraviolet and infrared printed codes can also be inspected with ease

To ensure that the correct label material has been used, a verification of the label material can be carried out

It ensures that all elements within a print file are processed with no missing or duplicate parts.

Barcode ANSI/ISO grading and reporting to ensure linear barcodes, 2D/QR codes and GS-1 codes meet international standards.

Integration with "Track & Trace" applications for pharmaceuticals and agrochemicals for complete traceability

Integration with supplies, such as e.g. B. In-line inkjet printers, feeding devices, attaching devices, packaging and labeling devices for real-time tracking

VIDEO

Exhibitions

Meet this supplier at the following exhibition(s):

Other b+b Automations- und Steuerungstechnik GmbH products

Bespoken machines

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.