- Products

- Catalogs

- News & Trends

- Exhibitions

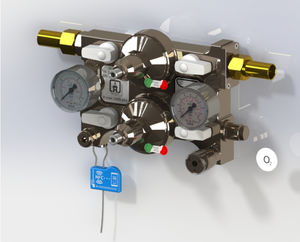

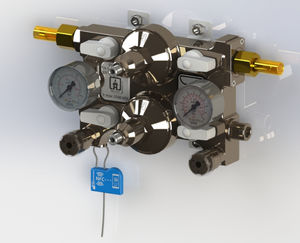

O2 pressure regulator HG160 SeriesairCO2N2O

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Fluid type

- O2, air, CO2, N2O, N2

- Applications

- medical

- Number of stages

- two-stage

- Inlet pressure

10 bar

(145 psi)- Output pressure

4.5 bar

(65.3 psi)- Weight

7.9 kg

(17.4 lb)

Description

The unit is made of two chemically nickel-plated brass castings, one casting for the regulators bodies, and the other casting for the zone shut-off valve; the regulator body has two decompression lines with two EURO/A regulators connected in by-pass through four ball valves, two on the inlet and two on the outlet of the same. A pressure gauge measures the system pressure upstream of the regulator; the area valve on the regulator body outlet has a ball valve on the inlet to shut off the gas and there is a fitting for a proximity sensor that reads the open/closed status of the valve, an emergency socket and a pressure gauge with electrical contacts. All the valve seats and pressure gauges are fitted with check valves to prevent gas leaks when servicing.The inlet and outlet connections are made using a Ø16 mm weld-on pipe. The unit also has a block for physical disconnection.If the 2nd stage unit with built-in area valve is installed outside the ward in the filter room, it can act as a shut-off module and therefore satisfy the threefold function of a fire shut-off valve, regulator module and zone shut-off valve, meaning notable time savings when installing and less building work.

Components

N.One regulator body made of cast CW614N chemically nickel-plated brass.

N.One zone shut-off valve body made of cast CW614N chemically nickel-plated brass.

N.One Ø16 mm weld-on pipe inlet connection.

N.One Ø16 mm weld-on pipe outlet connection.

N.One stainless steel filter.

N.Two shut-off valves upstream of each regulator with check valves.

N.Two shut-off valves downstream of each regulator with check valves.

N.One zone shut-off ball valve with check valve.

Catalogs

No catalogs are available for this product.

See all of BEHRINGER‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Gas pressure regulator

- Hospital flow meter

- Medical pressure reducer

- O2 flow meter

- O2 pressure regulator

- Humidifier

- Adjustable-flow pressure reducer

- Column flow meter

- Single-stage pressure reducer

- Air pressure reducer

- High-pressure pressure reducer

- Bubble humidifier

- CO2 pressure reducer

- N2O pressure regulator

- Two-stage pressure reducer

- Integrated pressure reducer

- Low-pressure pressure reducer

- Rail-mounted vacuum regulator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.