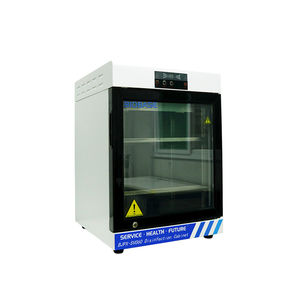

Medical autoclave BKM-K18B dentalbenchtopautomatic

Add to favorites

Compare this product

Characteristics

- Applications

- medical, dental

- Configuration

- benchtop

- Function

- automatic

- Sterilization chamber material

- stainless steel

- Capacity

18 l, 23 l

(4.76 gal, 6.08 gal)- Temperature range

Max.: 134 °C

(273.2 °F)Min.: 105 °C

(221 °F)- Width

630 mm, 680 mm

(25 in, 27 in)- Height

450 mm

(17.7 in)- Depth

485 mm

(19 in)

Description

The pulse vacuum autoclave extracts vacuum and fills steam into the sterilization room for many times to make the sterilization chamber reach a certain vacuum degree, and then fills saturated steam to reach the set pressure and temperature, so as to achieve the purpose of sterilization of the sterilized substance.

Features:

1. Brand-new operation interface: The LCD touch screen can display real-time information such as temperature, pressure, time, operating status, fault alarm, and equipment operating curve, making the sterilization information more intuitive and clear, and it is convenient for users to observe the operating status of the equipment.

2. Multiple safety protection devices: Automatic over-temperature protection device, multiple control and protection of evaporator, door safety interlock protection, double over-pressure protection device, etc.

3. Door structure: BKM-K18/23B autoclave adopts a manual door structure, BKM-Z18/23B autoclave adopts automatic door structure. It is could quick and convenient to operate, and effectively protects the human body and prevents burns.

4. Vacuum system: It adopts high-efficiency vacuum system, low working noise, ultimate vacuum can reach more than -80KPa, fast pumping speed, good dryness of items, and more thorough sterilization.

5. Diversified procedures: There are fast procedures, encapsulation procedures, rubber procedures, dressing procedures, liquid procedures, liquid customization, solid customization and other procedures, as well as B&D testing, vacuum testing procedures, and appointment procedures.

VIDEO

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Biobase sterilizer

- Biobase steam sterilizer

- Biobase medical sterilizer

- Biobase benchtop sterilizer

- Biobase automatic sterilizer

- Biobase stainless steel sterilizer

- Laboratory autoclave

- Dental autoclave

- Cleaner-disinfector

- Front-loading washer-disinfector

- Surgical sterilizer

- Autoclave with dryer

- Dental chair

- Electric autoclave

- Benchtop washer-disinfector

- Autoclave with sliding door

- Fixed dental chair

- Autoclave with cooling system

- Dental washer-disinfector

- Laboratory cleaner-disinfector

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.