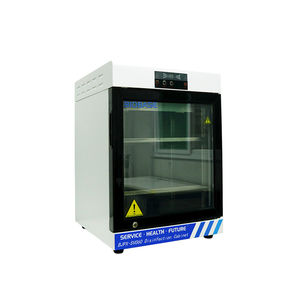

Medical autoclave BKQ seriesophthalmologyoperating roombenchtop

Add to favorites

Compare this product

Characteristics

- Applications

- medical, ophthalmology, operating room

- Configuration

- benchtop, horizontal

- Function

- programmable, with vacuum cycle

- Sterilization chamber material

- stainless steel

- Capacity

150 l, 200 l, 300 l, 360 l

(39.63 gal, 52.83 gal, 79.25 gal, 95.1 gal)- Temperature range

Max.: 134 °C

(273.2 °F)Min.: 105 °C

(221 °F)- Width

1,190 mm, 1,400 mm, 1,570 mm

(47 in, 55 in, 62 in)- Height

1,780 mm, 1,980 mm

(70.1 in, 78 in)- Depth

940 mm, 1,170 mm

(37 in, 46 in)

Description

The pulse vacuum autoclave extracts vacuum and fills steam into the sterilization room for many times to make the sterilization chamber reach a certain vacuum degree, and then fills saturated steam to reach the set pressure and temperature, so as to achieve the purpose of sterilization of the sterilized substance.

Features:

1. Sterilization data output: Standard micro printer, no need for separate external connection.

2. 7-inch color LCD touch screen, which can display information such as temperature, pressure, operating status, fault alarm, cause analysis, and solutions at the same time.

3. Strong vacuum drying system, the vacuum degree can be up to-92kpa, after drying, the residual humidity of device doesn't exceed 0.25%, the residual humidity of dressing doesn't exceed 1%.

4. The air in the chamber is sterile and avoids re-contamination.

5. Adopt quick-release side cover and top cover for easy maintenance and cleaning.

6. Micro-controller programmable control technology.

7. Full protective door cover, effectively prevent burns.

8. The equipment adopt self-expanding sealing ring, sealing performance is more reliable and stable.

9. The closing method adopts a multi-point pressing structure of the radiation rod, safe and reliable.

10. The equipment is connected to the water source without manual replenishment. After the customer chooses the program, the equipment can complete the whole process from water injection to drying without human intervention.

11. After the program is completed, the sound prompts sterilization to be completed.

Catalogs

No catalogs are available for this product.

See all of Biobase‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Biobase sterilizer

- Hospital cupboard

- Biobase steam sterilizer

- Biobase medical sterilizer

- Stainless steel cupboard

- Biobase benchtop sterilizer

- Biobase automatic sterilizer

- Biobase stainless steel sterilizer

- 1-door cupboard

- Single-module cabinet

- Laboratory autoclave

- Laboratory cupboard

- White cabinet

- Ultrasonic cleaner

- Front-loading sterilizer

- Dental autoclave

- Vertical autoclave

- Medical ultrasonic cleaner

- Autoclave with touchscreen

- Stainless steel ultrasonic cleaner

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.