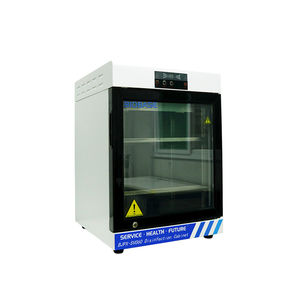

Laboratory autoclave BKQ-B50Vmedicalbenchtopvertical

Add to favorites

Compare this product

Characteristics

- Applications

- medical, laboratory

- Configuration

- benchtop, vertical

- Function

- programmable, electric

- Sterilization chamber material

- stainless steel

- Options

- with dryer

- Capacity

50 l, 75 l

(13.21 gal, 19.81 gal)- Temperature range

Min.: 105 °C

(221 °F)Max.: 134 °C

(273.2 °F)- Width

700 mm

(28 in)- Height

1,070 mm

(42.1 in)- Depth

610 mm

(24 in)

Description

1. Steam water internal circulation.

2. Pulse vacuum exhaust to ensure the effect of steam sterilization.

3. Mobile probe detects to ensure the internal temperature of liquid directly, to ensure the sterilization effect of liquid program.

4. LCD screen display shows pressure, temperature, time and error codes and operation curve etc.

5. Selectable programs for packed, unpacked, dressings, rubber, liquid, liquid custom, solid custom, sterilization of medium, dissolution of medium, B&D testing and vacuum testing etc.

6. Complete process of preheating, replacement, pulse exhaust, heating, sterilizing and drying run automatically.

7. 0.22μm Sterilization high efficiency air filter. The filtration efficiency is higher than 99.5%, ensuring that the vacuum-depleted air is sterile air to prevent re-pollution of sterile materials.

8. Standard built-in printer for recording the information during the entire sterilization process.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Biobase‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Biobase sterilizer

- Hospital cupboard

- Biobase cabinet refrigerator

- Biobase steam sterilizer

- 1-door refrigerator

- Biobase medical sterilizer

- Biobase laboratory freezer

- Biobase laboratory refrigerator

- Biobase 1-door freezer

- Automatic defrost refrigerator

- Stainless steel cupboard

- Rectangular table

- Biobase laboratory incubator

- Biobase benchtop sterilizer

- Refrigerator with glass door

- Biobase automatic sterilizer

- Biobase stainless steel sterilizer

- 1-door cupboard

- Laboratory vacuum pump

- Electric refrigerator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.