- Laboratory

- Sample management

- Robotic sample preparation system

- Chemspeed Technologies AG

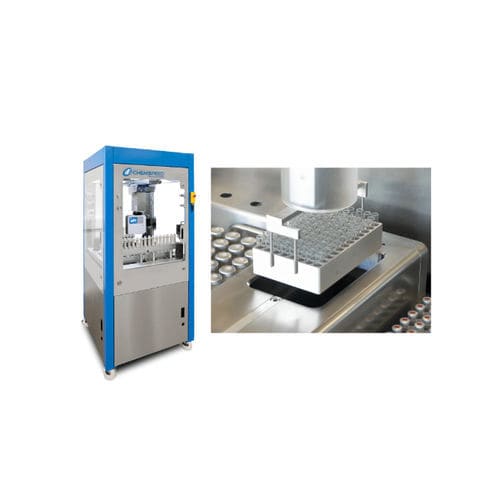

Fully automated sample preparation system FLEX CATSCREENroboticfor the pharmaceutical industrydosing

Add to favorites

Compare this product

Characteristics

- Operation

- fully automated, robotic

- Applications

- for the pharmaceutical industry

- Preparation type

- dosing

- Configuration

- benchtop

Description

Unattended catalyst preparation and screening at ambient and elevated pressure in versatile 96-well plates with disposable glass vials / reactors.

OVERVIEW

Chemspeed's solution

The leading technology in overhead gravimetric dispensing / dosing (patented) combined with our versatile, fully automated MTP / well-plate pressure block and our user-friendly software, enable you to accelerate, standardize and digitalize your catalyst synthesis & screening in flexible well plate formats (e.g. 12x20 mL, 24x8 mL, 48x2 mL, 96x1 mL total volume glass vials).

WORKFLOW

Example workflow

The interactive workflow panel below showcases example workflows for this solution. Each Chemspeed tool or module performs a set of specific actions, as in any manual lab workflow, and an almost limitless arrangement of these tools is possible.

BENEFITS

Powerful advantages

Catalysts preparation and screening at ambient and elevated pressure in versatile 96-well plates (1-100 bar), work-up, analysis.

Ventilated hood for inertization and safety.

Optimized footprint (3x3 ft, 90x90 cm) versus capacity - all while reducing costs and maximizing return on investment.

Unique fully automated MTP pressure block based screening with automated opening / closing, screening plate loading / unloading.

4-Needle Head for volumetric liquid handling and sampling.

Gravimetric solid dispensing into an unlimited choice of vial / plate / reactor formats.

The balance moves to the destination, increasing speed and efficiency.

Balance resolution of 0.1 mg or 0.01 mg.

A large dispensing range, from a few mg up to several grams.

Powder dispensing / dosing robotic tool can be combined

Catalogs

No catalogs are available for this product.

See all of Chemspeed Technologies AG‘s catalogsRelated Searches

- Chemspeed sample preparation system

- Chemspeed automatic sample preparation system

- Chemspeed laboratory sample preparation system

- Chemspeed benchtop sample preparation system

- Chemspeed liquid handling sample preparation system

- Laboratory automation platform

- Chemspeed modular sample preparation system

- Chemspeed floor-standing sample preparation system

- Chemspeed fully automated sample preparation system

- High-throughput sample processor

- Liquid handling laboratory automation system

- Blood sample processor

- Washing sample processor

- Research sample preparation system

- Extraction sample preparation system

- Chemspeed mixing sample preparation system

- Chemspeed pharmaceutical sample processor

- Purification sample processor

- Heating sample processor

- Chemspeed robotic sample preparation system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.