- Laboratory

- Laboratory infrastructure

- Laboratory workstation for the pharmaceutical industry

- Chemspeed Technologies AG

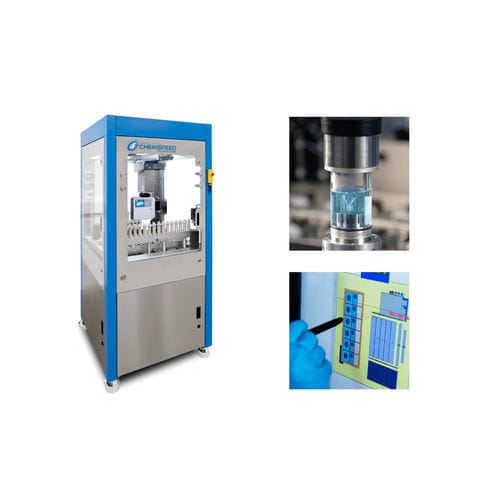

Laboratory workstation for the pharmaceutical industry FLEX FORMAXfor formulationfully automatedcompact

Add to favorites

Compare this product

Characteristics

- Applications

- for the pharmaceutical industry, for formulation

- Operation

- fully automated

- Configuration

- compact, modular

Description

FLEX FORMAX supports your digitalization process with automated workflow solutions for faster and better formulation development and formulation optimization. FLEX FORMAX modularity allows the user to execute and perform complex formulation workflows. High quality is assured by e.g. accurate viscosity, pH, temperature and stirring control.

OVERVIEW

Chemspeed's solution

Chemspeed’s FLEX FORMAX allows fully automated formulation on less than one square meter.

A typical FLEX FORMAX deck consists of up 6 precision formulation vessels in 1 formulation module, 3 overhead gravimetric dispensing robotic tools, a variety of racks with vials, syringes, heated and disposable pre-formulation vessels and much more.

As alternative a deck with 12 precision formulation vessels (150 ml) in 2 formulation modules is feasible without additional racks.

The FLEX FORMAX PERSONAL has the unique capability to exchange Robotic Tools and therefore change it's functionality on the fly, resulting in:

Several tools on one single platform

A cost effective robotic platform with a smart footprint

Easy programming

The robot brings functionalities as dispensing, analytics and actions to the Precision Formulation Vessels

Add solids, powders, liquids, highly viscous materials to the milligram resolution while the formulation is being processed

On the working area FLEX FORMAX has up to 2 formulation modules

The formulation module is a working entity consisting of 6 individually controlled, high precision formulation workstations. Each workstation with its own vessel / blender, feed vessel and syringe pump can be customized and controlled to match almost any formulation workflow.

VIDEO

Catalogs

Workflow Portfolio

32 Pages

Related Searches

- Laboratory workstation

- Benchtop laboratory workstation

- Automated laboratory workstation

- Floor-standing laboratory workstation

- Compact laboratory workstation

- Modular laboratory workstation

- Fully automated laboratory workstation

- Laboratory workstation for the pharmaceutical industry

- Sampling laboratory workstation

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.