- Products

- Catalogs

- News & Trends

- Exhibitions

Fully-automatic filling machine RADIO FILLfloor-standingplug-and-playfor liquids

Add to favorites

Compare this product

Characteristics

- Operational mode

- fully-automatic

- Configuration

- floor-standing, plug-and-play

- Product applications

- for liquids

- Application domain

- for the pharmaceutical industry, for radiopharmacy

- Other characteristics

- aseptic, with peristaltic pump, with isolator

- Options

- with capping system, with checkweigher

- Production capacity

40 p/h, 300 p/h

Description

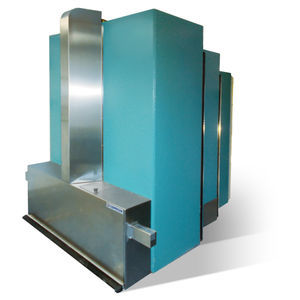

Large batch production aseptic vial filling system

The Radio Fill is a fully automated solution, for large batch production of radiopharmaceuticals. The Radio Fill concept is an ALL IN ONE, filling-stoppering & capping machine.

Monoblock solution, including the Class C shielded isolator and automatic system for feeding of empty vials.

Radio Fill is conceived for any customer who need a Plug&Play technology who require a short product placement on the market. The 100% IPC control of the dosing guarantee a high quality of the final product.

The newest model of Radio Fill has seen a deep redesign, with increased speed up to 300 vial/h (based on dispensing range from 0.5 to 10 ml filling volume). Radio Fill is designed for filling of RTU (ready to use) vials in trays. Radio Fill can also be connected to an autoclave for final sterilizing.

RADIO FILL - Radiopharmaceuticals large batch production system

Highlights

Modular platform for automatic filling of large batch

Aseptic environment

Filling speed: up to 40 pcs/min

Filling accuracy: +/- 1%

IPC 100% check weighing

No Vial – No Fill system

Flexible closure system compatible wih Stopper / AluCap / PushFitCap

Reject station (camera for stopper/caps)

Plug and Play

Product & Packaging Material

The Radio Fill has been specifically designed for Aseptic Liquid Filling

It can be used for big batches, with RTU Vials in trays

Automatic or semi automatic loading and accumulation of vials on rotating table

Wide range of vials can be adopted, with minimum format changes and short time impact

Automatic or semi automatic discharging systyem of filled vials.

Related Searches

- Comecer filling machine for the pharmaceutical industry

- Comecer automatic filling machine

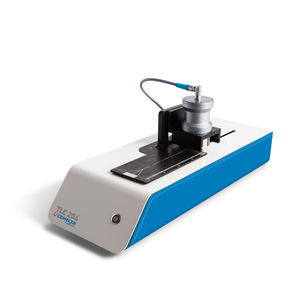

- Leak tester

- Comecer floor-standing filling machine

- Liquid filler

- Pressure leak tester

- Decontamination machine

- Benchtop leak tester

- Semi-automatic filler

- Compact filler

- Compact leak tester

- Vial filler

- Comecer aseptic filling machine

- Volumetric filler

- Decontamination station for the pharmaceutical industry

- Automatic leak tester

- Filler with capping system

- Rotary filler

- In-line filler

- Compact decontamination machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.