- Products

- Catalogs

- News & Trends

- Exhibitions

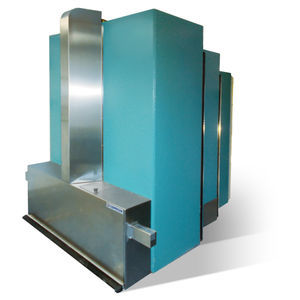

Dispensing shielded cell BBST seriesfillingfor radiopharmacystainless steel

Add to favorites

Compare this product

Characteristics

- Applications

- dispensing, for radiopharmacy, filling

- Other characteristics

- stainless steel

- Air flow type

- laminar flow

Description

The shielded isolators series, mod. BBST, is a family of Class A radiopharmaceutical isolators, equipped with laminar flow on the entire main chamber. They can house automatic modules or fractioning systems in sterile conditions and in observance of cGMP regulations.

Modular design and flexible configuration

Touch screen for hot cell and dispensing system

Airtight connections for radioactive fluids

Fluid supply lines made of AISI316L stainless steel with ball shut-off valves

DOP test connections (filter leakage test)

Internal pressure automatic adjustment by modulating valves

Designed for housing automatic modules or fractionation systems in sterile conditions

High sensitivity tele-pliers (movement by ball bearings)

Semi-automatic bubble point test touch screen controlled

VPHP connections with hot cell and pre-chambers (manual valves, automatic optional)

Dose calibrator (available in the versions 2 Ci or 20 Ci) with touch screen console

Product extraction system (Drawing System)

cGMP compliant

Illuminate™ MI: IIoT manufacturing intelligence platform and factory-floor management.

The shielded isolators series, mod. BBST, is expressly dedicated to filling, calibrating and fractioning operations on vials/syringes.

The machine is ideal for small/medium vial productions (batches of 10-15 vials per batch) and, if requested expressly, for small syringe productions (batches of 3-5 5 ml syringes per batch). The cell guarantees maximum protection for the operator against ionising radiation through complete shielding, the air seal between the chambers and the use of tele-pliers.

VIDEO

Related Searches

- Upright refrigerator

- 1-door refrigerator

- Laboratory refrigerator

- Stainless steel cupboard

- Laboratory incubator

- 1-door cupboard

- Stainless steel refrigerator

- Laboratory fume extractor

- Laboratory cupboard

- Stainless steel laboratory incubator

- Biological safety cabinet

- 1-station hand wash basin

- Metal sink

- Stainless steel hand wash basin

- Class II biological safety cabinet

- Comecer aseptic isolator

- Comecer floor-standing isolator

- Pass-through

- Floor-standing biological safety cabinet

- Carbon dioxide laboratory incubator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.