- Products

- Catalogs

- News & Trends

- Exhibitions

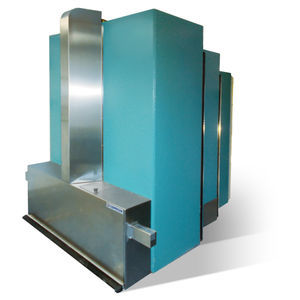

Radiopharmacy shielded cell MIP seriesfor radioisotope preparationsynthesisfor research

Add to favorites

Compare this product

Characteristics

- Applications

- synthesis, for radiopharmacy, for radioisotope preparation, for research

- Other characteristics

- negative pressure, stainless steel

Description

The series of shielded housings model MIP has been designed to host automatic modules for routine production or research equipment of radioisotopes and radiopharmaceuticals for experimental use. The series has been designed to guarantee radioprotection to the operator and the utmost decontamination and cleaning procedures effectiveness. The work chamber is sealed, shielded on every side and kept under negative pressure.

The MIP shielded cell is available in two sizes: 1100 mm and 1390 mm (work chamber width).

Shielded Cells for Synthesis Modules Model MIP | Comecer

Modular design and flexible configuration

Available in Pb 75 or 100 mm shielding

7” touch-screen operator panel to check and trace the critical parameters of the machine both in “at rest” or “in operation” mode

Working chamber air quality complies with Class B “At rest” (EEC-cGMP)

Airtight connections for radioactive fluids

Fluid supply lines made of AISI 316L stainless steel with ball shut-off valves

DOP test connections (filter leakage test)

Product extraction system (Drawing System)

Illuminate™ MI: IIoT manufacturing intelligence platform and factory-floor management.

The cell is shielded on all sides with 75 mm or 100 mm thick lead. Shielded door with lead glass window.

The working area is made of AISI 316L stainless steel with Mirror-Bright surface finishing.

Turbulent flow internal ventilation kept in continuous negative pressure. Perfect door closing is ensured by a system of inflatable gaskets placed around the door’s perimeter.

The MIP cell is equipped with Comecer Drawing System, allowing the extraction of the vial without opening the cell, ensuring safe conditions for the operator.

Related Searches

- Upright refrigerator

- 1-door refrigerator

- Laboratory refrigerator

- Stainless steel cupboard

- Laboratory incubator

- 1-door cupboard

- Stainless steel refrigerator

- Laboratory fume extractor

- Laboratory cupboard

- Stainless steel laboratory incubator

- Biological safety cabinet

- 1-station hand wash basin

- Metal sink

- Stainless steel hand wash basin

- Class II biological safety cabinet

- Comecer aseptic isolator

- Comecer floor-standing isolator

- Pass-through

- Floor-standing biological safety cabinet

- Carbon dioxide laboratory incubator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.