- Products

- Catalogs

- News & Trends

- Exhibitions

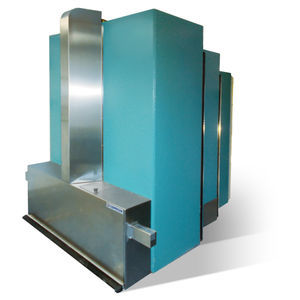

Radiochemistry fume hood FHR1-FHR3floor-standingactivated carbonstainless steel

Add to favorites

Compare this product

Characteristics

- Applications

- radiochemistry

- Configuration

- floor-standing

- Filter type

- activated carbon

- Structure material

- stainless steel

- Other characteristics

- stainless steel

Description

The work area is fully made of AISI 304 INOX stainless steel. The surface is finished with Scotch-BriteTM. All the joints are made by suitably smoothed and ground arc welds in an environment of inert gases. All the structure is hardened by means of box-type INOX steel sheets. The worktop is equipped with a raised edge in order to prevent the leakage of contaminated liquids.

The hood is closed at the front part by an acrylic glass slide rail which runs between the polizene lateral guides.

The tool rack panel is on the hood front lower wall. This instrument panel is made of 15/10 thick, AISI 304 stainless steel, and is an integral part of the worktop. The remote controls of the fluids (liquid and gaseous) as well as the electrical outlets are on the instrument panel. The supply of these fluids is done by means of taps placed on the hood internal side panels, which are connected to the feed manifold.

Features of radiochemistry fume hood

Front closing with Plexiglas vertical sliding door

Adjustable by-pass of the air flow

Double-walled aspiration system, frontal air speed of 50 cm/sec

Filtration system with absolute and activated carbon filters integrated into the hood structure

Protected replacement of the filter with canister equipped with gullet for the positioning of the barrier sack

Controlled discharge of radioactive liquid waste into a polyethylene bin with a capacity of 20 litres, electric gear case with external capacitive level probe, automatic interruption of the water flow when the container is full

Remote control for adjusting the hot/cold water

Starting and interruption of the water through the use of photoelectric cells controlled by the operator’s feet

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.