- Products

- Catalogs

- News & Trends

- Exhibitions

Radiopharmacy air compression system ACSstationary

Add to favorites

Compare this product

Characteristics

- Applications

- for radiopharmacy

- Configuration

- stationary

Description

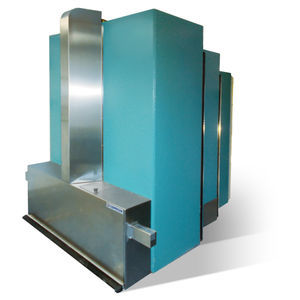

The system collects potentially radioactive air from inside hot cells during radiopharmaceutical production or after a malfunction of the synthesis modules.

Highlights

Up to 16 cells connected to the same system and up to 5 boxes in production simultaneously.

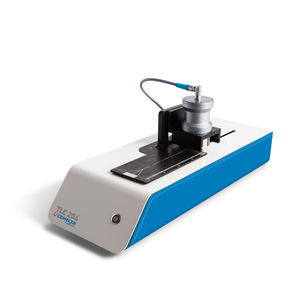

Three-valve system mounted on each cell (2 pneumatic valves and 1 electric valve)

Pressure gauges are used to measure the positive and negative pressure in the extraction circuit.

200-litre air accumulation tank and 200-litre storage tank

50-litre vacuum tank with storage function

The membrane compressor is used to compress the air flow and create negative pressure in intake mode

Illuminate™ MI: IIoT manufacturing intelligence platform and factory-floor management

The extracted air is then sent to a compression system and stored inside pressurised tanks. A Geiger probe, placed inside a Marinelli system (optional), monitors these tanks. Once the stored radioactive activity has decayed, the air, no longer contaminated, is discharged in the extraction conduit of the laboratory general ventilation.

The compression station can manage one or more COMECER production or handling cells.

Moreover, the compression station can be connected to the cyclotrone vacuum pump. In the event of an accident or failure of the target, the contaminated air is stored in the relative tanks.

Release the full potential of ACS with Illuminate™ Manufacturing Intelligence

Use real-time machine performance data to pinpoint where to focus efforts to reduce downtime, maximize line throughput, improve product quality, and make sustainable production improvements.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.