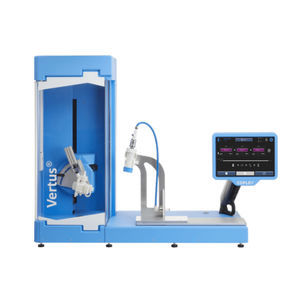

Flow sensor 8100for the pharmaceutical industry

Add to favorites

Compare this product

Characteristics

- Evaluation type

- flow

- Applications

- for the pharmaceutical industry

Description

Both DDU and APSD data can be severely compromised if the inlet flow rate (the flow rate at the entrance to the induction port or DUSA) used during testing is inaccurate and/or inconsistent, generating discrepancies with regard to its effects on both the cascade impactor itself and the inhaler under test. Copley offers solutions with the required range and accuracy to measure the flow in inhaler testing systems.

Designed and manufactured using Copley expertise, the Flow Rate Sensor FRS ensures consistent and accurate inlet flow rate measurement for delivered dose uniformity (DDU) testing and aerodynamic particle size distribution (APSD) measurement. The FRS is tailor-made for use with a Copley Flow Controller to determine and control test flow rate in an optimised orally inhaled and nasal drug product (OINDP) testing system.

Volumetric mode: Calculation of flow rate base on live T/P conditions

Standard mode: Calculation of flow rate based on pre-set T/P conditions

Bi-directional air flow measurement

Rapid data output for in-depth analysis

Low flow resistance

Technical Specifications

Operation principle:

Thermal (MEMS)

Standard flow rate range:

-200 to +200 StdL/min

Standard flow rate resolution:

0.1 StdL/min

Standard flow rate accuracy:

Typically +/-1.75 % of reading

Maximum +/- 2.5 % of reading

or ± 0.2 StdL/min, whichever is greater

Volumetric Flow Calculation

Accurate calculation from in-built T & P sensors

Flow resistance:

< 4 kPa at 200 StdL/min

Volumetric flow calculation:

Yes

Inlet filter

Required

Connectivity:

Interface to external devices, such as:

– Breath Actuation Controller BAC 100i

– Critical Flow Controller TPK 100i

– PC

Catalogs

Copley-Inhaler-Testing-Brochure

150 Pages

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.