- Products

- Copley Scientific

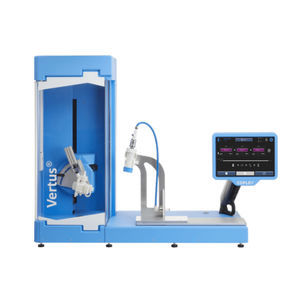

MDI fast screening impactor 5260for DPIs

Add to favorites

Compare this product

Characteristics

- Product applications

- for DPIs, for MDIs

Description

The concept of Abbreviated Impactor Measurment (AIM) is founded on the basis that once the full Aerodynamic Particle Size Distribution (APSD) profile of the product has been established in development using a full-resolution cascade impactor (and the process validated) then for product batch release testing and QC applications, it is possible to use simpler but highly sensitive metrics, solely to determine if the product is fit for purpose. This is known as Efficient Data Analysis (EDA).

Based on proven NGI Preseparator technology, the Fast Screening Impactor (FSI) represents a purpose-made approach to AIM that separates the dose into Coarse Particle Mass (CPM) and Fine Particle Mass (FPM) making it suitable for AIM-HRT application (i.e. FSI-HRT) for MDIs, DPIs and nasal sprays. A range of inserts are available, to generate a 5μm cut-off diameter within the flow rate range of 30-100 L/min at 5 L/min intervals, making it ideal for DPIs tested at a flow rate that equates to a 4kPa pressure drop over the inhaler. A range of different insterst are also available with a range of cut-off diameter/flow rate combinations, allowing for an FSI-QC version, with a cut-off diameter selected close to the product’s MMAD.

Catalogs

Driving Results in Inhaler Testing

163 Pages

Copley-Inhaler-Testing-Brochure

150 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.