- Laboratory

- Laboratory infrastructure

- Medical vacuum pump

- Copley Scientific

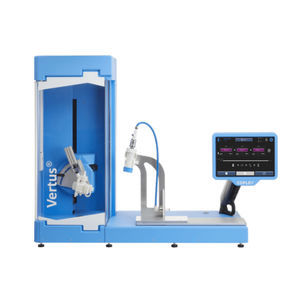

Laboratory vacuum pump SCP6for inhalerselectronicrotary

Add to favorites

Compare this product

Characteristics

- Applications

- laboratory, for inhalers

- Technology

- electronic, rotary

- Options

- lubricated, portable

- Flow

Min.: 0 l/min

(0 us gal/min)Max.: 683 l/min

(180.43 us gal/min)- Weight

71 kg

(156.5 lb)- Width

433 mm

(17 in)- Height

455 mm

(17.9 in)

Description

Driving most OINDP testing systems is the vacuum pump. We offer a choice of three pumps dependent on the set-up concerned and the capacity required.

Super Capacity Vacuum Pump

Capable of generating sonic (P3/P2 ≤ 0.5) flow rates through the Next Generation Impactor (NGI) up to 100 L/min, the SCP6 provides a maximum unregulated flow of 683 L/min, ideal for DPI applications. Designed to provide a viable alternative to the use of two HCP6 pumps to provide these conditions, the SCP6 can also be used for MDI, nebuliser and nasal product testing applications via a flow control valve, which regulates the flow rate between 0 and 280 L/min.

Low maintenance

Advanced sound insulation

Oil-lubricated rotary vane

Left and right vacuum inlets – choose where to place pump in system

Dual filtration process ensures there is virtually no oil vapour in the exhaust air, making it suitable for use in a laboratory environment

Vacuum Pump Technical Specifications

Type:

Rotary vane

Lubrication type:

Oil

Max. sonic flow through NGI:

100

Max. vacuum level:

<0.1 kPa

Applications:

MDIs, DPIs, Nebulisers, ADIs, Nasal Products

Routine maintenance:

Oil/filter change

Catalogs

Driving Results in Inhaler Testing

163 Pages

Related Searches

- Laboratory vacuum pump

- Positive-displacement vacuum pump

- Climatic test cell

- Temperature test cell

- Hospital vacuum pump

- Humidity test cell

- 1-door test cell

- Digital control unit

- Medical controller

- Lubricated vacuum pump

- Temperature controller

- Flow controller

- Test chamber for the pharmaceutical industry

- Electronic vacuum pump

- Rotary vacuum pump

- Portable vacuum pump

- Humidity control panel

- Benchtop test cell

- Automated controller

- Compact test cell

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.