- Laboratory

- Laboratory infrastructure

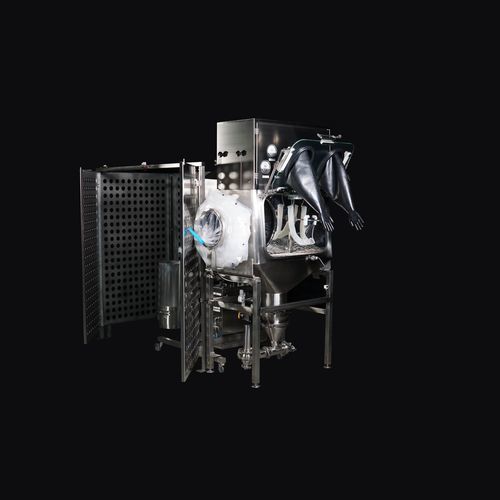

- Floor-standing glove box

- CSV Containment

Emptying drum glove box OEB4-5floor-standing

Add to favorites

Compare this product

Characteristics

- Applications

- for emptying drums

- Configuration

- floor-standing

Description

The entire CSV Containment product range is designed and tailor-made to suit the customer's containment or confinement needs. From isolators to accompanying accessories, with us you can find all the products you need! Let's take a closer look at the Drum Discharging Glove Boxes.

Powder transfer operations are made safer by the double iris on the Drum Discharging Glove Boxes, which are also prepared for pneumatic transfer. The Drum Discharging Glove Boxes are equipped with a pneumatic lifter fully protected by safety grids.

The lifter allows through some quick and simple maneuvers, the entry of drums of different diameters and weights into the chamber. All operations, including opening and closing the double containment irises, can be automated. Different recipes can be programmed, to be recalled according to the types of processing being done.

The iris system can be considered universal because of its great versatility. Once the material has been safely transferred and the drum unloaded, the operator can also conveniently carry out bag out operations. The chamber is equipped with a door connected to a continuous liner system made by CSV Containment. CSV Containment also manufactures lump-breaker systems to complete the supply.

Main features of the Drum Discharging Glove Boxes:

• Double Drum Iris Technology (DIT®) for drums docking.

• Automatic Lifting system for drums.

• 2 gloves in each chamber.

• WIP system with PTFE Spray Gun.

• DN 300 Continuous liner as waste bag out.

• HMI panel for equipment monitoring.

• Fan (ATEX) integrated in the casing of the isolator.

• Feeder valve ValvEngineering.

• Bottom T-Shape pipe for Pneumatic transfer system connection.

VIDEO

Catalogs

No catalogs are available for this product.

See all of CSV Containment‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.