- Furniture, Logistics

- Logistics, Service, Storage

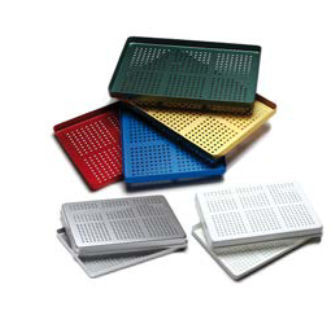

- Dental tray

- DENTAL MARKET s.r.l.

Dental instrument tray TD30 seriesaluminumperforated

Add to favorites

Compare this product

Characteristics

- Applications

- for dental instruments

- Material

- aluminum

- Other characteristics

- perforated

Description

In our facilities in Italy, we produce aluminium and stainless steel items, including impression trays, instruments, a complete line of omnitrays and endodontic boxes, as well as surgical kits that can be fully customised as to design and brand.

• Entirely made in Italy in our plants in Tuscany.

• Full laser customisation.

• Ready-to-order stock for catalogue items.

• Totally adaptable production process.

• Minimal quantities of goods can be ordered and customised for new projects according to the customer’s drawings and designs

Alox 360

Our Project of Metal customisation

Alox stands for Alu (aluminium) and Inox (stainless steel), namely, the two metals we process in any shape. It is our new project of customisation of raw material into objects tailored to your work. A few features are listed below to make you better understand what we mean by customisation:

• Dimensions We carry out your project or advise you.

• Colours Aluminium anodising process Green, White, Red, Yellow, Blue

• Logo Adding your logo printed in 1 colour.

• Finishing Surface treatment: satin-finishing or electropolishing

• Packaging Both format and graphics are customisable.

Made in Italy

Fully made in our plants in Tuscany.

Raw Material

Use of top quality stainless steel and aluminium.

UNI ISO 13485:2016

UNI ISO quality certification guaranteed.

Logo

Printing of your logo or other details (codes, reference numbers, etc.). 1-colour screen printing.

Dimensions

Create your item taking into account the proper dimensions for your work.

Finishing

Feel free to take care of details and finishing. Do not limit your creativity.

Colours

5 colours available.

Catalogs

No catalogs are available for this product.

See all of DENTAL MARKET s.r.l.‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.