Scan software didex 3D printingmodelingmanufacturing

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Function

- scan, 3D printing, modeling, manufacturing

- Applications

- for dental laboratories

- Area of the body

- gingival, jaw

Description

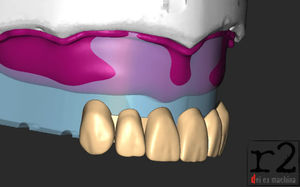

The didex program is the first software to prepare a digital jaw model scan for 3D printing of a PINDEX* model. For the first time and for a long time, didex combines efficient 3D printing technology with the requirements of a precision dental model. Haptics and appearance correspond to the familiar plaster model. The pinned and plaster-socketed dental arch provides dental technicians with maximum accuracy and result transparency. Friction and fitting of the dies meet the requirements of a master laboratory for the first time. The model, which is articulated in a familiar way, is perfect proof of an intelligent combination of state-of-the-art manufacturing technology with the requirements of a precision craft.

Extension for high-precision implant models

With this module, high-precision implant models can now also be realized in the stand-alone software didex. Thanks to the integrated implant library, in which various companies (e.g. NT-Trading, Medentika) are stored, an implant model - with a removable gingival mask - can be created for almost any situation. didex thus combines efficient 3D printing technology with the requirements for accurate saw-cut, situation and now also implant models. In this way, the classic and, in many cases, indispensable dental working basis - the precision model - can be easily transferred to the modern world of digital dental technology.

Catalogs

No catalogs are available for this product.

See all of Dentona AG‘s catalogsRelated Searches

- Dental material

- Anatomy model

- Demonstration anatomical model

- Restoration dental material

- PMMA dental material

- Dental prosthesis dental material

- Modeling dental material

- Dental crown material

- Ceramic dental material

- Dental bridge material

- Biocompatible dental material

- Wax dental material

- Denture model

- Casting dental material

- Dental CAD/CAM material

- Dental software

- Milling dental material

- Translucent dental material

- Dental anatomical model

- Design software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.