- Dental

- Dental laboratory

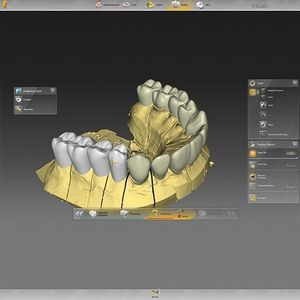

- Dental laboratory 3D scanner

- DENTSPLY MAILLEFER

Dental laboratory 3D scanner inLab MC X5benchtop5-axisSTL

Add to favorites

Compare this product

Characteristics

- Applications

- for dental laboratories

- Configuration

- benchtop

- Number of axes

- 5-axis

- File format

- STL

- Length

210 mm

(8.3 in)- Width

590 mm

(23.2 in)- Depth

580 mm

(22.8 in)

Description

inLab MC X5 is a universal production unit for wet and dry production of blocks and disks. It was designed to meet dental requirements in labs and focus on economic and effective production processes.

You benefit from a wide range of materials and can select from the high-quality materials of Dentsply Sirona and its CAD/CAM material partners for which the production processes of inLab MC X5 are optimized.

Why choose inLab MC X5?

Universal

inLab MC X5 can be used for dry or wet production depending on the material and indication. More than thirty years of experience in the wet processing of glass ceramics make this the ultimate professional machine for the wet grinding of fully contoured restorations from final-strength monolithic materials. Alternating between wet and dry production, e.g., from glass ceramics to zirconia, is fast and easy.

Broad range of indications

The application range for inLab MC X5 enables dental labs to make productive use of their equipment. Processable disc height and setting angles offer flexibility for manufacturing implant restorations with heavily diverging screw channels or abnormally shaped stumps.

Open

It is the perfect complement to the inLab components inEos X5 and inLab software but can also be used to process other STL restoration data, including implant-supported restorations with screw access channels. Having its own CAM module, the unit can be connected flexibly to other CAD systems.

Catalogs

No catalogs are available for this product.

See all of DENTSPLY MAILLEFER‘s catalogsRelated Searches

- Dental material

- Analysis software

- PMMA dental material

- Radiology software

- Control software

- Heating furnace

- Ceramic dental material

- Scheduling software

- Monitoring software

- Benchtop furnace

- Dental CAD/CAM material

- Translucent dental material

- Milling dental material

- Dental software

- Design software

- Scan software

- 3D printer

- Treatment software

- Zirconium dioxide dental material

- Dental milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.