- Medical & Pharmaceutical industry

- Components for the medical industry

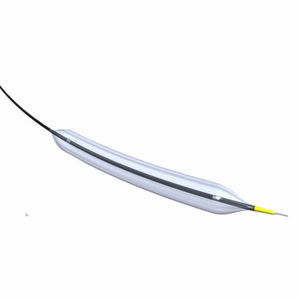

- Catheter manufacturing tubing

- Dutch Technology Catheters

- Products

- Catalogs

- News & Trends

- Exhibitions

Catheter manufacturing tubing PTFEstraight

Add to favorites

Compare this product

Characteristics

- Applications

- for catheter manufacturing

- Material

- PTFE

- Configuration

- straight

Description

DTC & Manufacturing partner are celebrating the launch of their PTFE production line in Singapore opened in Q3 2022 and are joining a very elite group of companies worldwide. With the latest advancements in extrusion technology, we are able to produce the most versatile, thinnest, and highest quality PTFE Catheter liners.

Since discovery in the late 1930’s it has been the polymer of choice for many applications. This was mainly due to the unique properties of PTFE. With the lowest coefficient of friction of any polymer offered and an extremely broad working temperature range, PTFE is ideal for use in products such as catheters for delivery channels for medical devices and wire and cable insulation for aircraft. Because of its unparalleled chemical resistance, PTFE has become an ideal polymer for the chemical and analytical sciences as well. We extrude PTFE in various forms.

Key Properties:: Lowest coefficient of friction of any polymer, Chemical resistance (all common solvents, acids and bases) and inertness, ETO and autoclave sterilizability, Working temperature range -454°F (-270°C) to 500°F (260°C), Excellent dielectric insulating properties, Biocompatibility – certified USP Class VI n Flame rating – UL 94 VO, Limiting oxygen index- greater than 95

PTFE PROCESSING FORMS

Extrusions

Electrospinning

Expanded extrusions

Radio-opaque (bismuth and barium)

Others available upon request

APPLICATIONS

Catheter componentry

Wire and cable insulation

Furcation tubing for fiber optics

Analytical and fluid management tubing

Stent grafts

Other Dutch Technology Catheters products

OEM Catheter Products & Parts (Full assembly / PTFE / Shafts / FEP HS / Shafts etc)

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.