- Medical & Pharmaceutical industry

- Components for the medical industry

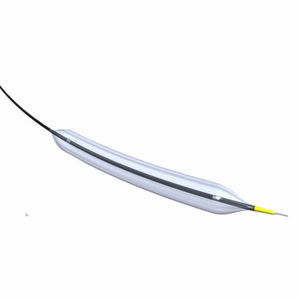

- Catheter manufacturing tubing

- Dutch Technology Catheters

- Products

- Catalogs

- News & Trends

- Exhibitions

Catheter manufacturing tubing stainless steelPVDFPTFE

Add to favorites

Compare this product

Characteristics

- Applications

- for catheter manufacturing

- Material

- PTFE, stainless steel, PVDF

- Configuration

- flat

Description

DTC & Partners use proprietary techniques for providing thin-walled, braided, and coiled catheters that range from 1.5F to 28F. We collaborate with you for analyzing the right balance between column strength, resilience, kink resistance, and torque response in the thinnest wall to meet the performance needs.

Multi-Lumen Shafts

Braid to coil conversions

Deflectable and fixed curve shafts

Multi-durometer shafts

Variable pitch coils and pick count braids

Braid – OD from 2F to 26F, single wall density down to 0.005 in/0.13 mm

Coil – OD from 1.5F to 28F, single wall density down to 0.003 in/0.08 mm

Outer Jacket – polyamide, polyether block amide (PEBA) & urethane, custom blends

Wire:

Round, Flat, and Ribbon

Stainless Steel, aramid, and Fabric

The diameter of the wire is from 0.0005” to 0.010”

Liners:

Fluoropolymer: PTFE, FEP, eFEP, eTEP, PVDF, PFA custom liners

Thermoplastic: polyamide, PEBA, PU, PE

Others: polyimide, PEEK

Marker Bands – gold, platinum, radiopaque polymers

Secondary Operations – funneling, curving, bonding, porting, tapering, and tipping

There are single and multi-durometer options available

Custom material fusion, color concentrates, and radiopaque fillers

Different variety of braid thickness and configurations that allow you to customize your catheter’s mechanical properties

There are secondary processes provided for braided catheters like tip forming, flaring, catheter reflow, welding, and coating

Hydrophilic and anti-microbial coating options are available

Other Dutch Technology Catheters products

OEM Catheter Products & Parts (Full assembly / PTFE / Shafts / FEP HS / Shafts etc)

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.