- Products

- LED radiometer

- DYMAX Europe GmbH

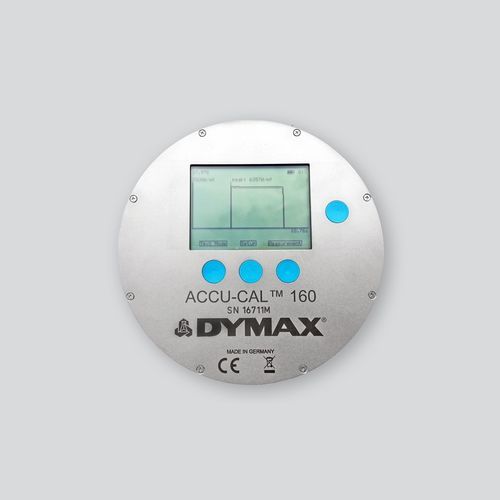

LED radiometer ACCU-CAL™ 160UV

Add to favorites

Compare this product

Characteristics

- Options

- LED, UV

Description

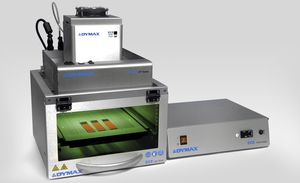

Consistent light-curing requires periodic monitoring of light intensity or dose. The ACCU-CAL™ 160 radiometer greatly simplifies both validating and monitoring a light-curing process. This radiometer is available in both UV and LED versions and can measure light up to 10 W/cm2 emitted from stationary light-curing flood lamps or lamps used in conveyorized processes. It can be used to determine intensity (measured in mW/cm2) or total energy as derived from intensity and exposure time (measured in mJ/cm2). The unit is simple to operate and can be controlled manually via four buttons on the faceplate or by a USB remote interface. Measurement results are displayed on the integrated LCD display or transmitted by the USB remote interface to a computer.

Two Reasons to Use a UV Radiometer

Validating and Maintaining a Light-Curing Process – A radiometer provides a quantifiable measurement that verifies if the light-curing process is operating within the qualified parameters. Since all UV bulbs degrade over time, the radiometer will reveal the optimal time for bulb replacement in a UV-curing device. Radiometers provide the same monitoring control for light-curing processes that thermometers provide for thermal processes.

Measuring Transmission Rates Through Substrates – A radiometer can be used to measure the light transmission rates of various wavelengths through substrates that absorb various frequencies of energy. To assure an effective curing process it is critical to measure the light intensity reaching the cure site below any intervening substrate.

VIDEO

Catalogs

LIGHT-CURING EQUIPMENT

28 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.