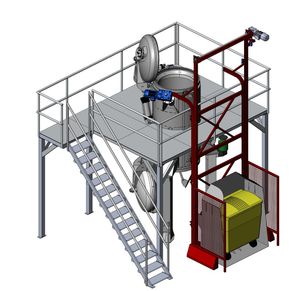

Medical waste treatment system T100automaticon sitewith shredder

Add to favorites

Compare this product

Characteristics

- Domain

- medical

- Operation

- automatic

- Configuration

- on site

- Options

- with shredder, pressure seal

Description

Our patented process is designed to shred and sterilize infectious waste to reduce its volume, and render its components unrecognizable all in one fully enclosed and automated, stainless steel, system. It combines shredding, direct steam and high pressure to treat infectious materials.

The contaminated waste is loaded into the upper chamber where a heavy-duty, high-torque, low speed shredder reduces the waste into small pieces.

Using gravity, the processed material drop into the lower treatment chamber, where every particle is steam heated to 138°C (280 F) and pressurized to 3,5 bar (51 psi) for 10 minutes. The operating and treatment conditions are continuously monitored and validated to achieve complete sterilization (Microbial inactivation = 108).

After the cooling process, the final product is volume-reduced (by up to 80 %), rendered unrecognizable and safe to recycle or to dispose as ordinary municipal waste.

The 30 minutes duration of an average cycle process is fully automated and totally monitored. A computerized control system scans the process and automatically prints a batch report at the end of each cycle with the essential sterilizing parameters for accurate record keeping.

VIDEO

Catalogs

ECODAS T100

2 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.