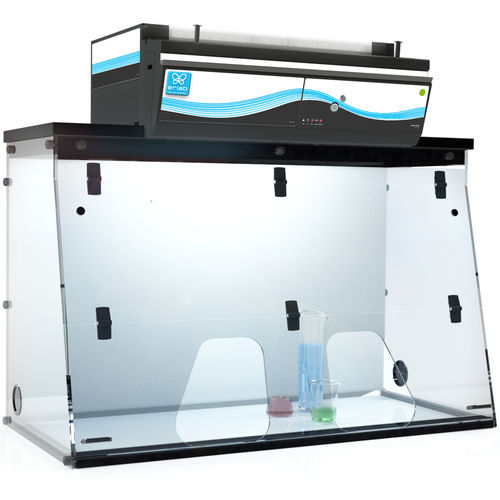

Chemical fume hood 481laboratorybenchtopductless

Add to favorites

Compare this product

Characteristics

- Function

- chemical

- Applications

- laboratory

- Configuration

- benchtop

- Exhaust mode

- ductless

- Face velocity

Min.: 0.4 m/s

(1.3 ft/s)Max.: 0.6 m/s

(2 ft/s)- Power

65 W

- Depth

620 mm

(24.41 in)- Height

1,110 mm, 1,285 mm

(43.7 in, 50.59 in)

Description

-Exclusive Erlab filtration technologycombining activated carbon and HEPA/ULPA to adapt to the manipulation

-Meets AFNOR NFX 15 211/ANSI Z9.5-2012 filtration efficiency standard (class 1 and 2)

-Real time sensors to detect main filter saturation with solvents, acids or formaldehyde

- Safety filter in case of main filter saturation

-Air face velocity permanent monitoring

-Erlab Safety Program: application analysis and validation, usage framework certification, usage follow-up

-Connected device allowing reception of safety notifications and use status

Simpler to use

Real time status communication by light and sound pulses:

-Air face velocity decrease

-Main filter saturation

-Fan failure

-Excess scheduled working time

Flexibility

-Modular filtration column adapting to application changes

-Easy and fast relocation

Savings

-No ductwork cost

-Annual energy cost < 100 €

-Compared to an extraction fume cupboard, energy savings compensate filter replacement cost

Environment

-No chemical release into the atmosphere

-Low energy consumption

Ask for the highest level of filtration

performances Powerful light guided communication

Connect your equipment and benefit from the remote access thanks to our mobile solutions

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Single-module cabinet

- Erlab laboratory fume hood

- Erlab laboratory cabinet

- Erlab microbiological safety cabinet

- Erlab laboratory microbiological safety cabinet

- Erlab benchtop fume hood

- Erlab laboratory material cabinet

- Erlab class II microbiological safety cabinet

- Erlab chemical fume hood

- Sterile isolator

- Booth

- Floor-standing biological safety cabinet

- Class III isolation chamber

- Erlab floor-standing fume hood

- Biosafety cabinet with HEPA filter

- Ventilated wardrobe

- Erlab HEPA fume hood

- Containment isolation chamber

- Erlab laminar flow fume hood

- Erlab EN 12469 microbiological safety cabinet

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.