Spraying dryer POLARDRY® laboratoryR&Dpilot

Add to favorites

Compare this product

Characteristics

- Drying method

- spraying

- Applications

- laboratory, R&D, pilot

Description

Introducing the Future of Spray Dry & Microencapsulation

The patented PolarDry® Electrostatic Spray Dryer utilizes revolutionary electrostatic technology which drives water to the shell and active to the core, lowering the evaporation temperature and eliminating active ingredient loss, degradation, or denaturalization. Harnessing the electrostatic effect, the dispersed active driven into the core is microencapsulated, virtually eliminating surface active, resulting in stunning encapsulation efficiency.

A portable PLC controlled once-through design intended for small-scale feasibility tests. This GMP designed machine is specifically sized to fit in most lab & fume hoods.

A portable PLC controlled once-through design intended for a laboratory environment. This GMP designed machine is the best option for feasibility checks.

A semi-portable PLC controlled recirculating system for R&D Environments. This unit uses the same nozzle as 032 and 050 to simplify the typical development work required to scale up from one machine to the next. This model includes portable access stairs with a work platform.

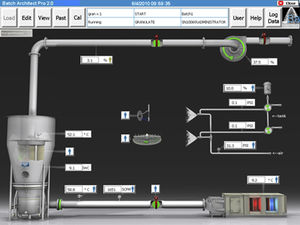

Model 032 is a modular design, PLC controlled system for Pilot Environments. Choose from Batch ArchitectTM or Batch Architect ProTM with CFR 21 PART 11 Compliant Data Logging to control this intermediate system. This model includes access stairs with a work platform.

Low Operating Temperature

Our spray dryers utilize electrostatic technology to drive water to the outside of the droplet allowing us to dramatically lower operating temperatures from the traditional ~200 °C to ~80 °C.

VIDEO

Catalogs

Complete catalog

99 Pages

Catalog 12 - Tablet Coating

14 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.