High-shear granulator PHARMX®for the pharmaceutical industryR&D

Add to favorites

Compare this product

Characteristics

- Applications

- for the pharmaceutical industry, R&D

- Other characteristics

- high-shear

Description

Efficient Mixing and Granulation

PHARMX® high-shear granulators are fully customizable bottom-driven mixing systems engineered to provide homogeneous mixing and efficient granulation. Equipped with an in-bowl, bottom-driven mixing impeller and side-mounted chopper, the PHARMX ensures uniform mixing across a range of R&D, pilot, and production size models.

Laboratory-scale units provide effective high-shear granulation for small batches.

Mid-sized systems offer a wide range of options for processing larger batches intended for clinical trial or small-scale production.

Large scale systems for granulating very large batches (up to 1250 Liters).

Uniform Mixing

The dome shaped lid permits product to perform a complete roll over as it moves up the side of the vessel wall. This ensures efficient mixing even when running at larger operating capacities.

Constant Tip Speed

One of the single most important factors in high shear granulation scale up is tip speed of the impeller and chopper tools. Along with tool and bowl geometry, each PHARMX bowl is designed to maintain a constant maximum tip speed across the entire line of models. Each tool has infinitely adjustable tool speed so that scale up from lab to pilot to production is predictable.

Safely Process Hazardous Compounds

For processing potent compounds requiring total containment, we are able to provide customized interchangeable bowls. The bowls can be removed from the console and placed in a glove box/flexible containment structure without any dusting of product from the bowl. Charging and discharging from the mixer bowl is completely contained.

Catalogs

Complete catalog

99 Pages

Related Searches

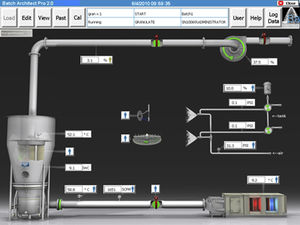

- Control software

- Reporting software

- Monitoring software

- Automated software

- Design software

- Server software

- Laboratory grinder

- Pharmaceutical industry grinder

- Drying dryer

- Granulator for the pharmaceutical industry

- Software for the pharmaceutical industry

- Coater for the pharmaceutical industry

- Rotor grinder

- Dryer for the pharmaceutical industry

- Fluid bed dryer

- Tablet coater

- High-speed mill

- Impact mill

- High-shear granulator

- R&D dryer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.