Fluidized bed dryer 002for the pharmaceutical industrydryingR&D

Add to favorites

Compare this product

Characteristics

- Drying method

- fluidized bed

- Applications

- for the pharmaceutical industry, drying, R&D, pilot, clinical

Description

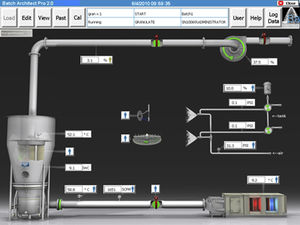

Optimized Drying, Coating & Granulation

Fluid Air fluid beds are the industry leader in air moving technology using the highest pressure, highest flow process blowers. High pressure blowers assure even the heaviest material have proper lift to fluidize and process efficiently. Variable frequency drive assure the exact amount of horsepower is delivered to the system for perfect airflow. Design flexibility ensures peak performance for fluid bed dryers, granulators, and coaters. Whether you need solid dosage technology for R&D, pilot or production applications, Fluid Air can help.

Our MAGNACOATER® Wurster coaters are the most robust with features that include, even air distribution, adjustable bed plate design, nozzle screens, tapered partitions, in-process adjustable partitions, self-clearing and removable nozzles, perimeter air enhancement, superior spray nozzle design, self-monitoring liquid delivery systems, and an Ultrasonic nozzle option. MAGNAFLO® fluid bed dryer/granulators and MAGNACOATER® Wurster coaters are completely customizable fluid bed systems designed to provide superior performance for a range of solid dosage processing applications.

Laboratory-scale units provide effective drying, coating or granulation for small batches.

Mid-sized systems offer a wide range of options for processing larger batches intended for clinical trial or small-scale production.

Large scale fluid bed systems for processing of very large batches (up to 1200 Liters).

VIDEO

Catalogs

Complete catalog

99 Pages

Related Searches

- Control software

- Reporting software

- Automated software

- Monitoring software

- Design software

- Server software

- Laboratory grinder

- Pharmaceutical industry grinder

- Drying dryer

- Granulator for the pharmaceutical industry

- Coater for the pharmaceutical industry

- Software for the pharmaceutical industry

- Rotor grinder

- Tablet coater

- Dryer for the pharmaceutical industry

- Impact mill

- High-speed mill

- Fluidized bed dryer

- High-shear granulator

- R&D dryer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.