- Medical Technical Facilities

- Healthcare IT, Telemedicine

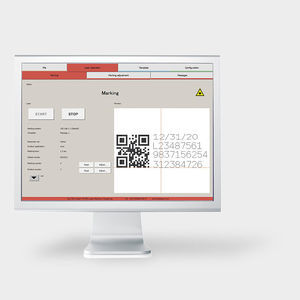

- Control software

- FOBA Laser Marking + Engraving, ALLTEC GmbH

Control software Middlewarefor communicationlaser markingmedical

Add to favorites

Compare this product

Characteristics

- Function

- for control, for communication, laser marking

- Applications

- medical

- Type

- automated

Description

Choose the easy way: All relevant laser marking parameters centrally controlled with FOBA Middleware!

You have the task of integrating a laser into a special machine with X, Y and Z axes and possibly even a rotary (swivel) unit? Or do you want to integrate a laser into an automated production line, equipped with motorized Z-axis for adjusting different working distances for several products? Would you also prefer controlling all the parameters relevant to marking from one program?

FOBA Middleware software solution package has been developed for the easy integration of FOBA's basic laser marking systems into your production environment. It facilitates installation and setup, and also ensures a continuously reliable and user-friendly marking process.

Comprehensive control via one software, only TCP/IP connection is required for the PLC

Machine hardware (PLC, axes, motors, rotary/swivel unit, machine door, rotary table) according to your own choice, only PLC program for communication with FOBA system required

Catalogs

No catalogs are available for this product.

See all of FOBA Laser Marking + Engraving, ALLTEC GmbH‘s catalogsOther FOBA Laser Marking + Engraving, ALLTEC GmbH products

Software for Laser Processing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.