- Medical Technical Facilities

- Healthcare IT, Telemedicine

- Reporting software

- FOBA Laser Marking + Engraving, ALLTEC GmbH

Laser marking software AOP NT Advancedreportingvalidationverification

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Function

- reporting, validation, verification, laser marking

- Applications

- medical

Description

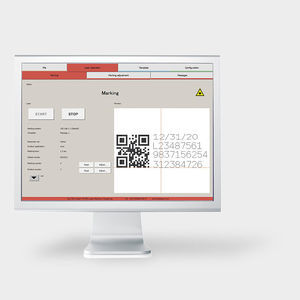

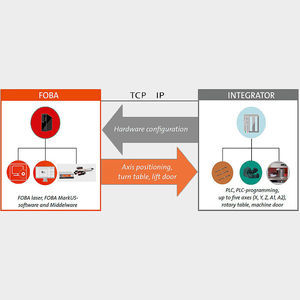

FOBA's Advanced Operator PlugIn NT (AOP NT) is a focused graphical user interface for FOBA laser marking equipment. The PlugIn is directly integrated in FOBA's MarkUS marking software, and has been designed for improving production efficiency, reducing costs and increasing throughputs during the laser marking process in the medical technology field as well as various other industries.

In the AOP NT, the essential steps of the marking process are clearly visualized in order to ensure a quick, intuitive, secure and almost error-free operation of the FOBA laser system. The simplified graphical user interface ensures for the fast, safe and reliable laser marking of all sorts of products, parts and devices. Protected from incorrect entries, a barcode scanner is used to transfer all job related data into the laser marking system. The marking process is fully visualized, including a part preview, clear operator instructions, marking process status information and direct feedback of code validation and mark verification results. Thus, the AOP NT helps to accelerate production processes and to reduce scrap during part marking which can add up to savings in the range of 40,000 Euro per year (given a 3 shift operation with 5 job changes per shift).

The visualized process, reduced to the essentials, minimizes operator tasks and reduces operating errors.Video, picture instructions and an intuitive GUI make the process easy to execute.

The focused marking process ensures greater production efficiency, reliability and throughput. The reject rate is reduced

Data integration by means of database connection MS Access (SAP, Oracle on request), History, reporting, logging.

VIDEO

Catalogs

No catalogs are available for this product.

See all of FOBA Laser Marking + Engraving, ALLTEC GmbH‘s catalogsOther FOBA Laser Marking + Engraving, ALLTEC GmbH products

Software for Laser Processing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.