- Laboratory

- Laboratory infrastructure

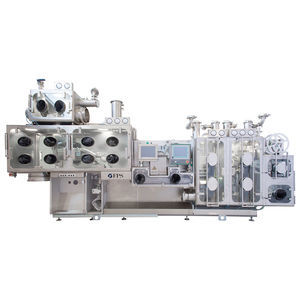

- Class III isolator

- F.P.S. Food and Pharma Systems

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Class III isolator RABScontainmentfillingpilot

Add to favorites

Compare this product

Characteristics

- Class

- class III

- Applications

- containment, filling, pilot, milling

- Type of products handled

- for toxic products

- Configuration

- floor-standing

- Other characteristics

- flexible

Description

Fully customized Aseptic Isolators that provide a total separation of the product from external contamination during processing. Aseptic isolators are routinely used within the pharmaceutical industry.

A sterile isolator allows avoiding the use of sterile cleanrooms, reducing the sterile volume around the process. Turbulent or unidirectional airflows can be adopted for ventilation.

FPS offers a range of totally contained aseptic solutions that covers the following applications:

Sterility testing

Aseptic filling lines

Vessel charging of sterile products

Dispensing

Sterile milling and micronization

Vessel discharge of sterile products.

Most applications include an integrated decontamination system (VPHP generator).

The RABS is the right choice for flexible and secure production in existing cleanrooms. A RABS can be designed as open or closed system (i.e. for toxic products), and can be active or passive. Each RABS is engineered and optimized according to the process requirements.

FPS offers:

Active RABS, complete with HVAC and T/RH control

Passive RABS, with control integration for process machine (filling line)

Retrofitting of existing units can be achieved in a relatively short period of time.

Catalogs

No catalogs are available for this product.

See all of F.P.S. Food and Pharma Systems‘s catalogsOther F.P.S. Food and Pharma Systems products

Containment Systems

Related Searches

- FPS floor-standing isolator

- FPS aseptic isolator

- Booth

- FPS class III isolator

- Laboratory booth

- Containment isolation chamber

- Laminar flow booth

- Pharmaceutical laboratory isolator

- HEPA cabinet

- Negative pressure isolation chamber

- Medical room

- Dispensing isolator

- Transfer isolation chamber

- Containment booth

- Laboratory room

- Flexible isolation chamber

- Sampling booth

- Clean room booth

- Custom isolator

- Filling isolator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.