This type of equipment is best for transferring potent API being processed from a process vessel to drums or bags, through a sieve.

These operations generate a lot of dust and exposure to high-potency APIs. Often the product is an API with highly toxic levels (up to OEL 10 µg/m3) and particle sizes can be irregular and PPE does not provide the required protection (e.g., OEB 5 – 0.1 µg/m3).

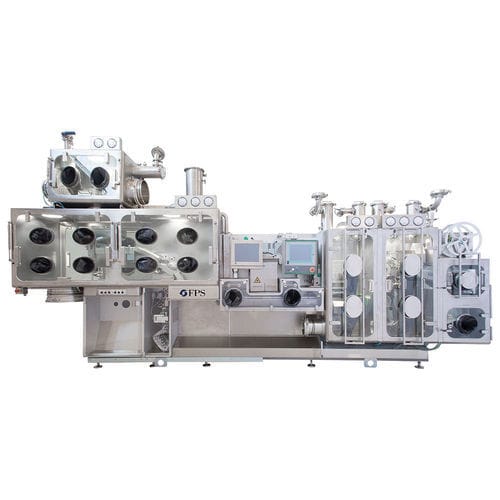

The advantages of FPS solutions are:

No risk of exposure to operators

Automated process: High productivity and 100% weighing accuracy.

Automated CIP system ensures highly efficient cleaning

No risk of cross-contamination after product changeover

Flexibility: powder can be fed into drums of various sizes

Easy-to-clean custom isolator with optimized ergonomics

FPS provides flexible solutions: for less toxic products (OEB3) windows can be opened because the continuous liner ensures sufficient containment with a wide range of bag sizes capable of receiving the processed product (system is on load cells)