- Furniture, Logistics

- Logistics, Service, Storage

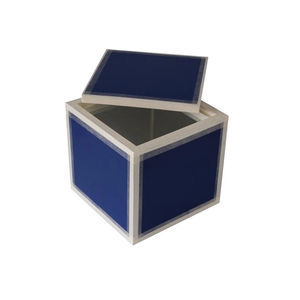

- Storage sample container

- Fujian Super Tech Advanced Material Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Vaccine sample box storagebiologicalblood

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Applications

- storage, for vaccines

- Sample type

- biological, blood

- Volume

Min.: 50 l

(13.21 gal)Max.: 200 l

(52.83 gal)

Description

The temperature during the process of vaccine delivery, loading, transportation, and storage must be strictly controlled, and the entire process needs to be maintained at 2-8 ℃ or -15-25 ℃ for dark and cold chain transportation and storage. It is required that even when there is a large temperature difference between the inside and outside of the box, the heat exchange rate can be slowed down, thereby playing a long-term role in maintaining heat or cold.

No power supply is required, and the entire low-temperature storage process uses phase change refrigerant refrigeration, which can maintain the temperature inside the box without using electricity. It is energy-saving and environmentally friendly, and can be reused, suitable for long-distance low-temperature transportation of drugs, biological reagents, blood and other products without electric refrigeration.

Advantages of Vaccine Carrier Box

01 Function

Insulation duration: 48-200 hours (4-8 days).

02 Convenient

Easy to assemble and disassemble.

03 Saving

It can be dismantled and stacked, reducing transportation volume and recycling costs.

04 Customization

No mold fee required, size can be customized.

05 High Energy

The measured ambient temperature is 35 ℃, and the insulation in the 2-8 ℃ temperature range is close to 200 hours (8 days).

06 Lower Logistics Recycling Costs

This tray insulation box is detachable and can be disassembled into six insulation boards stacked together when recycled or not in use, reducing the total volume by half; Whether it is the logistics cost when customers purchase products or the logistics cost when customers retrieve insulated boxes, there is a clear cost reduction.

Other Fujian Super Tech Advanced Material Co., Ltd. products

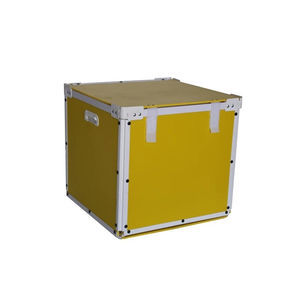

Assembled Insulated Box

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.