- Furniture, Logistics

- Logistics, Service, Storage

- Storage sample container

- Fujian Super Tech Advanced Material Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

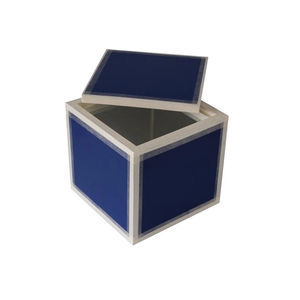

Storage sample box insulated

Add to favorites

Compare this product

Characteristics

- Applications

- storage

- Function

- insulated

- Volume

Min.: 50 l

(13.21 gal)Max.: 200 l

(52.83 gal)

Description

High performance VIP and PU composite.

High cost-effectiveness (long insulation time, low amount of refrigerant used).

Using high-strength plastic edge protection, paired with high-strength, collision resistant corner protection.

Customizable size.

Repairable and recyclable.

Environmentally friendly and pollution-free.

Usage: More stringent transportation conditions for pharmaceuticals, fresh products, food, etc.

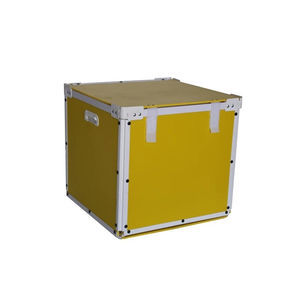

Advantages of Corner Protection Insulated Box

01 Lower Logistics Recycling Costs

This tray insulation box is detachable and can be disassembled into six insulation boards stacked together when recycled or not in use, reducing the total volume by half; Whether it is the logistics cost when customers purchase products or the logistics cost when customers retrieve insulated boxes, there is a clear cost reduction.

02 Simple Cargo Loading and Unloading Process

When loading goods, a forklift can be directly used to place the goods with pallets in the bottom tray of the insulation box from any direction, without the need for manual movement of the goods from the existing pallets into the insulation box, and then the insulation board can be clamped and assembled into a complete insulation box; The same applies when unloading goods. Greatly reduces the labor cost of transporting goods.

Other Fujian Super Tech Advanced Material Co., Ltd. products

Assembled Insulated Box

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.