- Products

- Laboratory pump

- Ginolis Ltd.

Laboratory pump PMBi dispensingbellowsfor liquids

Add to favorites

Compare this product

Characteristics

- Applications

- laboratory, dispensing

- Technology

- bellows

- Fluid type

- for liquids

- Configuration

- compact

Description

The patented Ginolis PMBi (Piezo Motor Bellows) pump technology provides high precision, non-contact liquid handling.

From 1000 µl all the way down to nanoliters

The PMBi pump is designed for accurate and repeatable dispensing of nanoliter range volumes.

The PMBi pump is available in two different models that are differentiated by the volume size.

50 nl)

<3% CV (@50 nl)

<8% (@2.5 nl)

Flexible

From 1500 μl down to single nL. The PMBi pump can be integrated into automation platforms and is also available in an easy-to-use starter kit.

Intelligent

Integrated pressure sensor for detecting clogs, leaks and air in fluid line, pump pre-pressurizing, and automated monitoring of pressure stabilization during pre-dispensing.

Low maintenance

PMB bellows system has no friction parts and is, thus, a pump with extremely long life and no need for replacement seals.

Dispensing technology

The basis of the Ginolis PMBi Pump is the highly accurate piezo motor that is connected to a bellows it contracts and expands. In doing so, the bellows displaces the volume in a closed chamber that is equal to the aspirated or dispensed volume.

The PMBi pump is equipped with a solenoid dispensing valve and a ceramic tip to dispense volumes as low as 1 nl. The dispensing pump displaces the volume of liquid defined by the user. The solenoid valve is opened for a short amount of time (100s of microseconds) to release a drop. The pump can dispense up to 100 drops per second.

Configurations

PMBi Pump starter kit for introductory applications

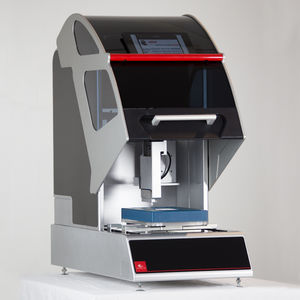

Cecilia dispensing platform for high precision dispensing of reagents and fluids on a compact scale

Catalogs

Ginolis PMBi Pump

3 Pages

Ginolis Cecilia-L

3 Pages

Other Ginolis Ltd. products

Microfluidic device manufacturing solutions

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.