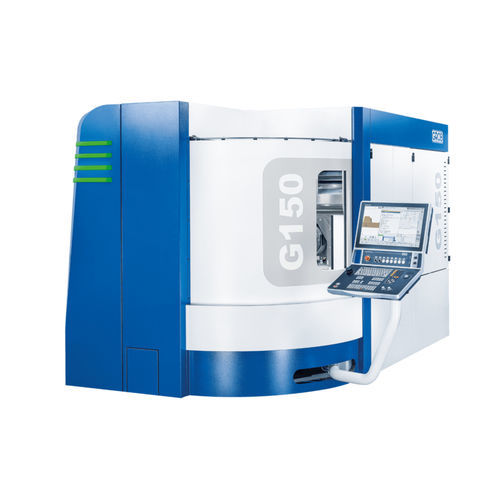

Medical industry machining centre G1505-axisspindleuniversal

Add to favorites

Compare this product

Characteristics

- Applications

- medical industry

- Number of axes

- 5-axis

- Number of spindles

- spindle

- Spindle orientation

- universal, horizontal

- Configuration

- compact

- Spindle speed

Max.: 42,000 rpm

(263,894 rad.min-1)Min.: 12,000 rpm

(75,398 rad.min-1)- Weight

13,400 kg, 15,400 kg

(29,541.94 lb, 33,951.19 lb)

Description

The G150 is the smallest universal machining center in the unique G-module concept of GROB and enables customers from various industries to machine with the highest precision.

With direct and absolute position encoders in all axes, the 5-axis machining center guarantees maximum accuracy for complex components and convinces with an innovative calibration and cooling concept.

The benefits at a glance

High productivity

Optimized availability

High visibility

Flexible applications

Maintainable

Compact design

Optimized access

Round-the-clock service

Unique machine concept

Horizontal spindle position

Axis arrangement

Overhead machining

Drive concept

Maximum stability

Large swivel range

Tunnel concept

Efficient machine cooling

Active cooling of heat-absorbing components/assemblies

Rigid spindle axis

thanks to the optimally positioned bearing close to the operating point

Unique overhead machining

with excellent chip fall and reduced thermal load in the part

Working with the usual familiar system

Possibility to choose between SIEMENS or HEIDENHAIN machine control systems

Ergonomic and safe

Perfect view of the machining operation through a laminated glass safety screen

Tilting rotary tables A-/B-axis

Choose between tilting rotary tables with T-grooves arranged in parallel (standard), as well as tilting rotary tables with pallet clamping system (option).In addition to the standard versions with an A- and B-axis, the "A-axis" (without B-axis) and "B-axis" (without A-axis) options are offered for the G150.

An optimum swivel range is achieved thanks to the compact designs of the compact rotary table and the motorized spindle contour.

VIDEO

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.