- Medical & Pharmaceutical industry

- Medical industry

- Automatic packaging system

- Hamer Packaging Technology

- Products

- Catalogs

- News & Trends

- Exhibitions

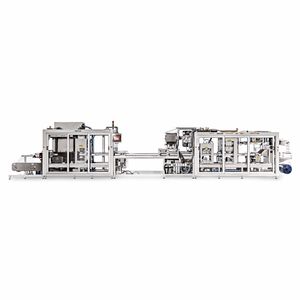

Automatic packaging system HM 30FFScompactfor sterile materials

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Type

- FFS

- Configuration

- compact

- Product applications

- for sterile materials

- Container type

- film, blister

- Application domain

- medical industry, for clean rooms

- Options

- sealing

- Weight

2,800 kg

(6,172.9 lb)- Width

1,300 mm

(51.18 in)- Height

2,000 mm

(78.74 in)

Description

The HM30 thermoformer is a compact FFS line specially designed to manufacture rigid packaging and their subsequent sterilization according to the requirements of the medical business.

Features

Dedicated to the production of short and medium runs.

Compact design and content size.

Pressure forming that allows the molding of film up to 0.8mm thick with precise molding.

Film traction by chain conveyor.

Low operating and maintenance cost.

PLC operated, touch-screen controlled.

Suitable for clean rooms.

Guarantees the packaging of medical products in accordance with GMP regulations.

Validable in accordance with existing medical regulations.

EU safety rules compliance.

Operation

The HM30 Medical integrates all the necessary operations for the manufacture of the blister according to the specifications necessary for clean rooms and validable according to specifications. The operations range from the thermoforming of the bubble from a roll, through the loading area, to the operations of sealing, individual punching of each of the figures and ejection of the finished blister.

ll diameter forming material (max.)

400 mm

Maximum thickness of forming material

0,8 mm

Forming material width (max.)

370 mm

Forming material width (min.)

230 mm

Forming area (max.)

350 x 200 mm

Forming area (min.)

200 x 150 mm

Height of forming below material level

60 mm

Forming pressure

2 bars

Capacity of vacuum pump

40 m3/h

Length of loading area

1.000 mm

Height of loading area

950 mm

Roll diameter sealing material (max.)

400 mm

Maximum thickness of lidding material

0,15 mm

Heater installed power

8 kW

Closing force sealing press

2.960 kg

Closing force trimming press

12.000 kg

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Automatic packaging machine

- Sealing packaging machine

- Blister packaging machine

- Compact packaging machine

- Medical industry packaging machine

- Film packaging machine

- Vacuum thermoforming machine

- Dental thermoforming machine

- Modular packaging machine

- Floor-standing thermoforming machine

- Sterile material packaging machine

- Automatic thermoforming machine

- Compact thermoforming machine

- Pressure thermoformer

- Industrial thermoforming machine

- Clean room packaging system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.