- Dental

- Dental instrument

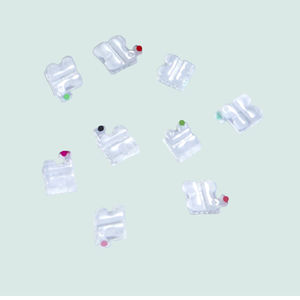

- Metal orthodontic bracket

- Hangzhou DTC Medical Apparatus Co. Ltd

Metal orthodontic bracket SL21-24self-ligatingminirectangular

Add to favorites

Compare this product

Characteristics

- Type

- metal, self-ligating

- Size

- mini

- Shape

- rectangular

- Other characteristics

- low-friction, nickel-free

Description

1 .made by metal injection moding (MIM) with 17-4PH stainless

steel.

2.with - tooth number in the cap for easy identification

3.passive - self-ligating brackets with low friction and light force

4.mini - size and low profile for patient comfort and easy control

5.laser welding technology to keep oral clean

6.sandblasted on mesh to enhance bonding strength

All of DTC brackets and tubes are made by laser welding technology instead of other Chinese factory which they use nickel brazing to weld the body and base.

Nickel brazing technology is using nickel as welding material between the body and base. As you all know, nickel is easy to flow into body and base during the process of nickel brazing, then it will affect the cleanness and bonding strength. And the most important thing, nickel is not very good for health and some patients are even sensitive to it.

Laser welding Technology means that we don't need to use any welding materials to weld the bracket/tubes body and base together. And the strength you can find the explanation above and it’s stronger than nickel brazing. It also keeps bracket body and base clean and slot accuracy. And without nickel material inside, the whole bracket will be lower profile.

Now DTC are the Only one factory who use Laser Welding technology in China for all of the orthodontic brackets and tubes! With this technology, you can feel safe to use DTC orthodontic brackets and tubes.

Catalogs

2020 DTC Catalog

30 Pages

Other Hangzhou DTC Medical Apparatus Co. Ltd products

Orthodontic bracket

Related Searches

- Grasping tweezers

- Straight tweezers

- Retractor

- Stainless steel tweezers

- Reusable tweezers

- Dental forceps

- Orthodontic bracket

- Dental mirror

- Dental retractor

- Oral spreader

- Metal orthodontic bracket

- Orthodontic elastic

- Autoclavable retractor

- Orthodontic tweezers

- Autoclavable mirror

- Ceramic orthodontic bracket

- Cheek retractor

- Self-ligating orthodontic bracket

- Aesthetic orthodontic bracket

- Twin orthodontic bracket

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.