- Medical & Pharmaceutical industry

- Pharmaceutical industry

- Filling and sealing machine for the pharmaceutical industry

- Harro Hoefliger Verpackungsmaschinen

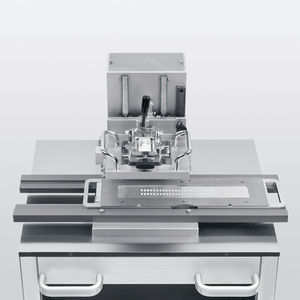

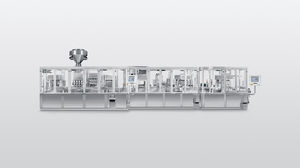

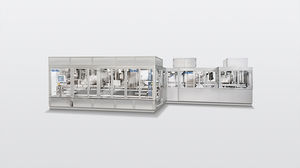

Filling and closing machine for the pharmaceutical industry VarioSys®semi-automaticaseptic

Add to favorites

Compare this product

Characteristics

- Applications

- for the pharmaceutical industry

- Operation

- semi-automatic

- Options

- aseptic

Description

VarioSys offers the ability to rapidly change processes for aseptic filling and closing of IV bags for the SKAN standard isolator PSI-L. The trolleys are equipped with nitrogen or argon rinsing, integrated evacuation, gassing, CIP-SIP capability and temperature monitoring. VarioSys is a highly flexible isolator solution for small batches as well as laboratory use.

Benefits

Aseptic production (Class A) in a clean room even of toxic products

One isolator, many options – can also be replaced with Bausch+Ströbel trolleys

Expandable with VarioSys system modules

Easy “lock and key” production change

Different closing technologies possible

Optional closing station for semiautomatic port setting

Technical data

Output: depending on operator

Compressed air: 2 m³/h (500 ml) – with retractive suction

Compressed air: 1 m³/h (500 ml) – without retractive suction

Dosing accuracy: 50 ml ± 1.5% up to 5,000 ml ± 0.3%

Final products

IV bags

Infusion bags

Periphery

Robot handling / pipetting

Aseptic web processing

Customized solutions

Liquid dosing

Dosing systems for liquids are used in the form of modules in pharmaceutical and medical production platforms at Harro Höfliger. This way, custom project requirements can be tailored as needed. The systems can be variably adapted to the defined performance specifications.

Assembly and connection

Bonded parts with irregular connection geometries can be permanently attached using ultrasonic welding technology.The laser welding method is ideal for fast, precise connections.

Trolley concept

The patented dosing trolley system allows the operator to quickly change the dosing method: Whether powder, pellets, tablets, micro-tablets or liquid

Catalogs

No catalogs are available for this product.

See all of Harro Hoefliger Verpackungsmaschinen‘s catalogsOther Harro Hoefliger Verpackungsmaschinen products

Dosing & filling

Related Searches

- Packaging system for the pharmaceutical industry

- Automatic packaging machine

- Filler for the pharmaceutical industry

- Floor-standing packaging machine

- Automatic filler

- Sealing packaging machine

- Blister packaging machine

- Compact packaging machine

- Filling and sealing machine for the pharmaceutical industry

- Medical industry packaging machine

- Liquid filler

- Film packaging machine

- Medicine packaging system

- Horizontal packaging machine

- Continuous packaging machine

- Table filler

- Vacuum packaging machine

- Intermittent packaging machine

- Semi-automatic filler

- Compact filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.